A proper containment strategy can be implemented, starting with a toxicology profile assessment performed by professionals in a pharmaceutical facility.

OEL values (Occupational exposure limits derived from toxicological data) are used by pharmaceutical industries as a starting point to determine the containment strategy to apply, in the case of both a new facility and an upgrade of an existing one. The application of risk management measures is essential to protect the safety of operators, a crucial issue in all industrial activities.

OEL are values to be respected also to prevent occupational disease, especially for workers exposed to toxic and highly active chemical substances in their workplace. Specifically, they establish the maximum concentration of a given substance to which a worker may be repeatedly exposed daily in a production facility without health risks.

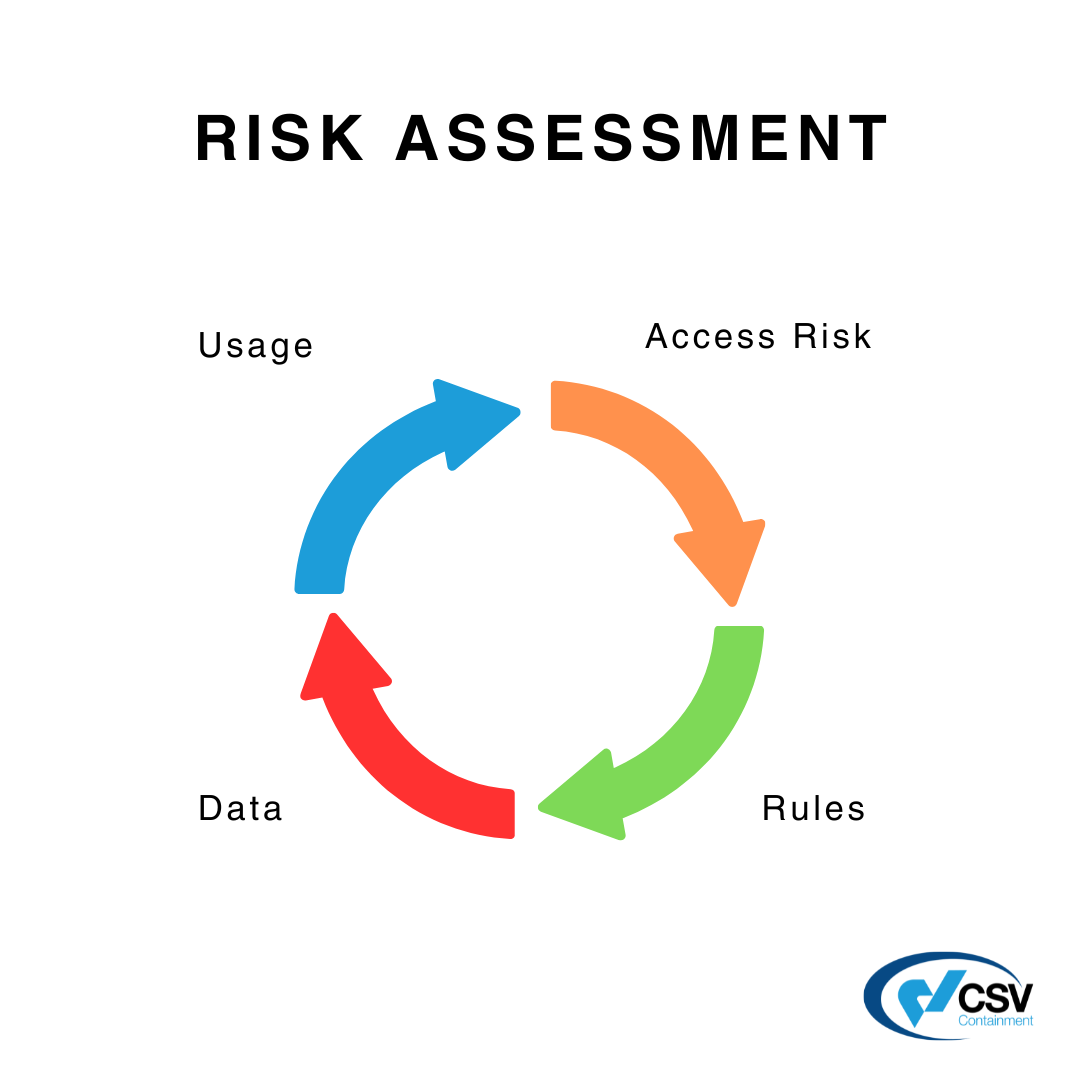

How can risk management measures be organized in response to a report?

CSV Containment can determine the best containment strategy to implement by drafting an Exposure control plan that helps the client in choosing which containment measures to take, based on the defined Occupational Exposure Bands (OEB). OEB is a process intended to quickly and accurately assign chemicals into specific categories (bands), each corresponding to a range of exposure concentrations designed to protect worker health.

Based on toxicological data, process engineers from CSV Life Science help CSV Containment experts to define the right exposure control strategy to achieve the OEB required. To identify the appropriate containment strategies to apply, it is, therefore, crucial to divide the analysis according to exposure scenarios: primary containment, secondary containment, and residual risk.

In the first scenario the process equipment, in the second one the site layouts and the environment conditions (pressure cascade), and in the third scenario the PPE and procedures as a whole are analysed.

The procedures considered are not only operational but regards also maintenance, cleaning, and decontamination. As mentioned above, the study applies both in the case of new industrial site development and in the case of renovations and can cover individual departments as well as entire production sites.

The containment practice defines the performance to achieve.

Risk analysis is based on the quantity of product handled, emission potential (moisture, grain size), and duration of operator exposure. This activity is quite structured and is aimed to:

- Evaluate the “as is” situation

- Identify solutions to contain the exposed operations on equipment and existing process flows.

- Investigate technologies other than those currently used, especially if they are more efficient, safer, and more likely to achieve higher containment goals.

- Identify any new or different technologies and process equipment

- Adjust personnel and material flows, if necessary

- Provide a timetable for implementing the necessary upgrade identified

- Provide a cost estimate of the necessary upgrade identified

The three pillars of ECP:

- Protection of personal exposure in work environments

- Quality of production

- Environmental sensitivity

CSV Containment can work to achieve these goals in synergy with CSV Life Science Group also in the engineering and construction phases. Finally, our teams of experts in containment are available to customers to identify the most appropriate solutions and share their know-how of tailored applications, from glove boxes to glove bags, not forgetting dedicated services such as SMEPAC testing.

CSV Containment provides tailor-made solutions for pharmaceutical and fine chemical sectors in terms of containment. For more info: containment@csv-ls.com