Watch the video!

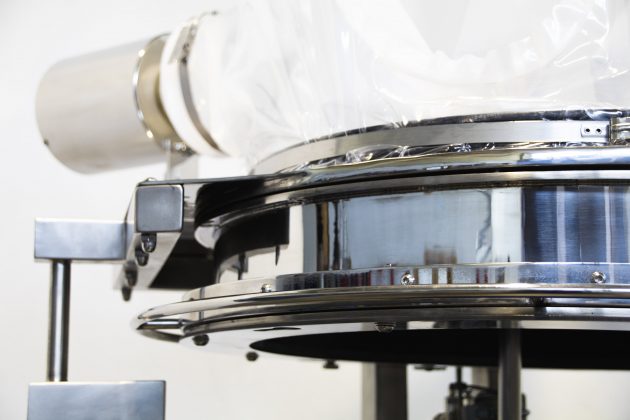

A flexible system to confine pneumatic powder transfer operations, not only because of the material of the isolator but also because of the flexibility in serving drums of different diameters.

Frequently, pneumatic systems operating in vacuum are used for pneumatic powder transfer operations, mainly to avoid handling drums and containers at height or on mezzanine structures. Both reactors and dryers can thus be easily accessed, as they often have elevated charging points. However, it is necessary at the same time to close operations of drum coupling drums and equipment transferring and charging. Usually, the device that creates the vacuum and conveys/collects the powder during the transfer is located at the charging point, on the top of the equipment, and is part of the transfer system. In other, less frequent cases, the plant vacuum or the receiving equipment produces the vacuum.

How does the dust-free pneumatic powder transfer solution designed by CSV Containment work?

The drum is placed on a pneumatic platform to lift it by driving it into a flexible chamber. The presence of nitrogen, both in the transfer circuit and in the chamber, must be taken into account, especially in explosive conditions. The pneumatic drum transfer unit is equipped with a vacuum breaker system with an absolute filter. The circuit thus composed is closed except for the volume surrounding the drum to be emptied, which is confined by an isolator placed above it. The flexible isolator ensures the sealing of the drum-chamber coupling using an iris (manual or automatic) of a universal size that can accommodate different drum diameters.

However, the high containment configuration is still possible and achievable through the following solutions:

- A double iris DIT® system

- A hybrid system with a single iris using bag-in/bag-out techniques for the bag in the drum or specific drum sleeves.

- A single iris with a zipped top, inside the chamber, to close the drum.

As for cleaning the pneumatic powder transfer station and the circuit, a properly equipped drum containing the washing fluid can be used. This allows for cleaning up the transfer circuit and, subsequently, exploiting the drum itself as a collection tank for chamber-flushing fluids carried out through an accessory spray gun.

Main features.

Manual and pneumatic iris versions are available.

- Pneumatic lifting saddle for drum

- DIT® system

- Flexible and tailor-made design for easy movements

- Compliance with any pneumatic/vacuum transfer system

- Light steel frame with wheels

- Conductive properties guaranteed

- Antistatic flexible chamber with two gloves

- Vacuum breaker system with an absolute filter

Upgradable from dust-free to highly potent containment performances system

CSV Containment provides tailor-made solutions for pharmaceutical and fine chemical sectors in terms of containment. For more info: containment@csv-ls.com