CSV Containment has developed the first double side iris station to allow greater versatility in the use of the universal drum loading system DIT®.

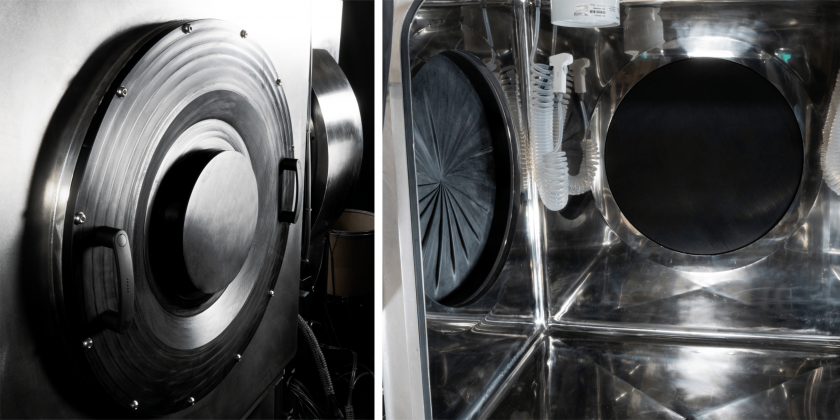

Having a dual access side with the drum and a single iris system, meaning the possibility of placing the double iris for lateral loading instead of at the back of the machine, is now achievable. We have equipped the airlock with a second porthole which, when appropriate, can be opened to accommodate the double iris present on the other side. This is, of course, a custom solution driven by the specific needs of the client, but it once again demonstrates the CSV Containment team’s adaptability to market demands.

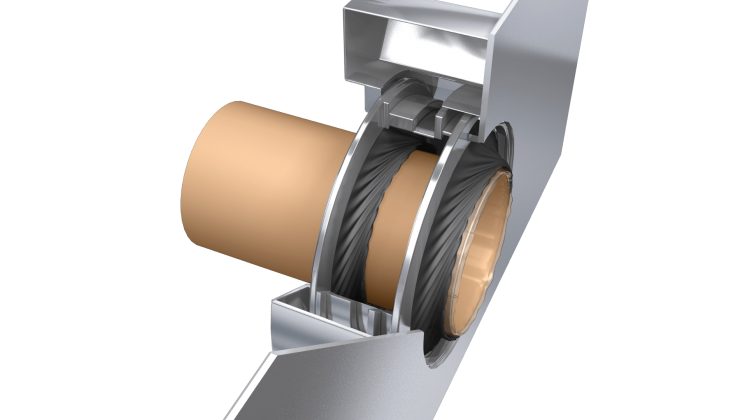

The DIT® system is the most versatile and safe drum loading solution in the CSV Containment product range. Available in both single and double versions, the elastomer iris is a practical and universal solution, capable of accommodating drums up to 560 mm in diameter. The automatic version (which can also be operated manually) can be enhanced with a system for storing the different drum sizes, so the desired loading preset can be selected via the control panel.

An adaptable drum reactor charging system.

![]()

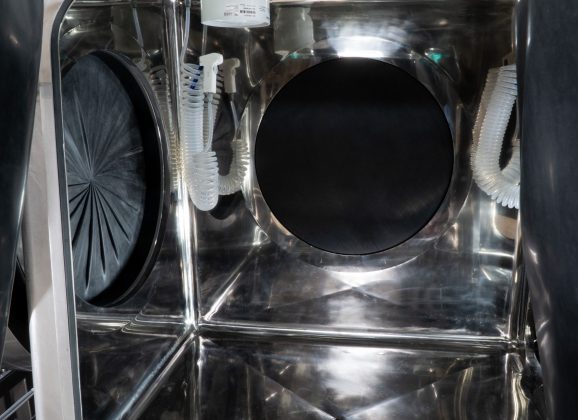

Drum reactor charging operations are facilitated not only by the dual position option for the iris but also by the internal door without a leaf that divides the two chambers. The transfer of bags from the airlock to the main chamber is unimpeded, thanks to the door equipped with an inflatable seal. The conical shape of the base of the loading chamber facilitates the transfer of powders to the reactor’s hatch and is equipped with a removable safety grid. Lastly, a dedicated door connects the chamber to a continuous liner system for bag-out operations. The liner, DN 300, is mounted on a canister with a dust collar that locks the film via a pneumatic valve.

The Main Features of the Double Side Iris System:

- Full GMP standard

- Containment target OEB 5

- Double Drum Iris Technology for drums docking

- Fully Automatic Drum Handling

- PE500 conductive door separating the chambers equipped with inflatable seal

- WIP PTFE Spray Gun

- DN300 steel made grooved canister for the waste bag out in continuous liner

- DN 300 Continuous liner (20 m long)

- Chambers Negative pressure control realised using Venturi device connected to a pressure regulator and a DN50/2” manual butterfly valve

CSV Containment provides tailor-made solutions for pharmaceutical and fine chemical sectors in terms of containment. For more info: containment@csv-ls.com