Working Safely with a Centrifuge: A Tailored Challenge for CSV Containment.

Creating a custom containment area around a centrifuge is made possible through the use of dedicated glove bags. The extensive experience gained in designing flexible isolators allows the technicians at CSV Containment to design ergonomic and safe structures for operators. Our containment experts also analyse all aspects in the field before outlining the most suitable solution for the client. Considerations include the equipment, processed products, solvents used, the volume of operations carried out daily, workspace, and the practical needs of the operators. All this data helps to establish the construction characteristics of the glove bags that will recreate an actual classified area around the centrifuge.

Creating the Right Atmosphere for Work.

Creating the Right Atmosphere for Work.

In the specific case of centrifuges, there is sometimes a need to modify the internal atmosphere. This can be done by inerting with a nitrogen flow injected into the glove bag through a convenient quick-connect fitting. It is also possible to create a sort of temporary cleanroom through filtered gas flow, to determine the recovery time needed to achieve a predefined cleanliness class relative to the background. The temporary cleanroom remains for the entire duration of the operations.

Continuous Support.

A ring is usually created to support the glove bag structure, secured with elastic cords. The flexible is stable yet at the same time allows good freedom of movement to facilitate operations around the centrifuge. The bag is attached to the centrifuge itself through steel profiles fixed to the ground and equipped with rounded corners, or alternatively, by directly fixing the isolator to the body of the equipment.

Regarding the passage of loading and unloading piping and utilities, a panel is often joined to the profile for through-wall transfer. In this case, the isolator is attached to the profile using a compression gasket (u-grip).

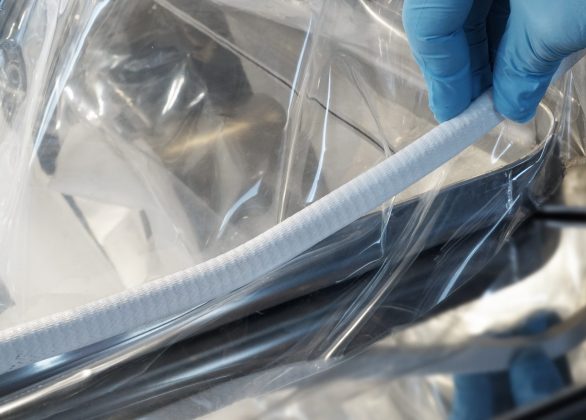

The transfer of the centrifuged product can occur through bag-out canisters in drum-liner or continuous-liner. In this case, too, the support of CSV Containment does not stop there, since a wide offer of produced liners, proprietary Twin Tie closure solutions, and the necessary tools are available to customers to complete all processing phases.

Certifications and Tests.

Our flexible isolators are designed to be easily replaced at each product campaign, although they can be easily decontaminated in organic solvent baths. In our “Flexilab“, we produce glove bags from certified and tested material, to guarantee the best performance for our customers. The care of dissipative materials is important when dealing with solvent-laden material. In this regard, in addition to certifying the material provided by our manufacturers, we subject the material to further internal quality controls. Electrical measurements are performed, for example, to ensure that they have not accumulated electrostatic charges to prevent possible ignitions. Finally, the after-sales service and supply of spare parts complete the range of services offered by CSV Containment.

CSV Containment provides tailor-made solutions for pharmaceutical and fine chemical sectors in terms of containment. For more info: containment@csv-ls.com