Supporting a client in the development of an API Pilot Plant is a highly stimulating challenge.

PolyCrystalLine entrusted CSV Containment with the task of designing glove boxes for their brand-new API Pilot Plant located in Southern Italy. The process development and production of an API is a sensitive and demanding task, especially when it involves handling a highly potent API.

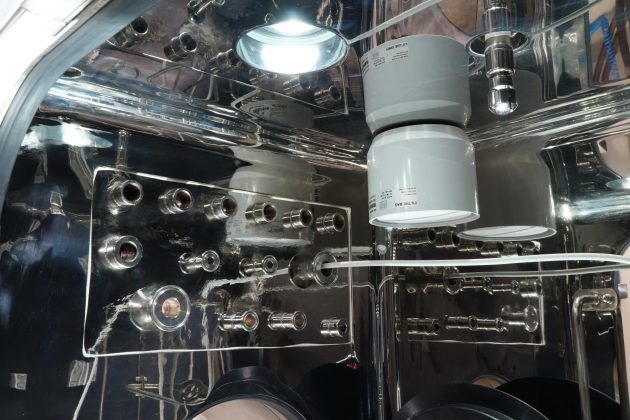

With at least a decade of experience in API research and development, PolyCrystalLine‘s needs are shaped by profound, direct field knowledge. CSV Containment collaborated closely with the client to deliver the best in terms of safety, production efficiency, and ergonomics. The input from operators, trained and experienced in working with glove boxes, has further refined the three rigid isolators designated for the API Pilot Plant. This state-of-the-art GMP production site guarantees operator safety and outstanding performance for clients. Recent SMEPAC tests conducted by our containment experts have yielded positive results, confirming an OEB5 category for each glove box in the facility.

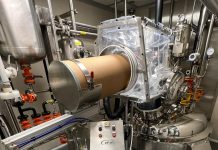

The three isolators installed at this site serve multiple purposes in the production phases of Highly Potent APIs. Foremost among these is the dispensing of samples, requiring a high degree of containment before loading the material into reactors through a closed-loop system, also ensured by continuous liners made by CSV Containment.

The process of isolating a highly potent material is a critical step. By installing a Nutsche filter within the isolator, key stages such as drying, unloading, and dispensing of the API can be conducted in a safe and contained environment.

Having a powerful tool like this isolator enables reactions up to 5L in a highly contained setting. Performing such a reaction in an autonomous reactor outside of a glove box like this would not be a viable option.

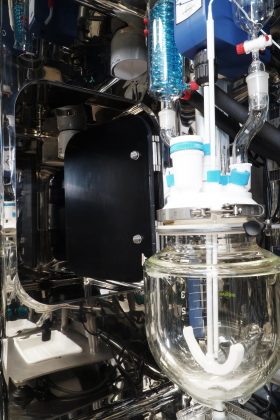

A dedicated glove box for the chemical lab.

Another rigid isolator had already been allocated to the chemical laboratory and houses two glass reactors, a chromatography column, and a pressure filter. We have discussed this in a previous article, which you can delve into by clicking here.

All three isolators are prepared for inertisation cycles and are equipped with a washing system using spray balls and spray guns for Clean and Wash in Place processes.

Small but beautiful.

Even though a pilot plant is a small-scale system, it is designed to understand the behavior of a process before its industrial-scale application. Therefore, every detail contributes to the success of production operations. The pilot plant is also crucial for identifying risks before final production and is thus a fundamentally important investment. CSV Containment offers its extensive containment expertise to support this delicate start-up phase, whether in a laboratory or a production facility. Tailoring solutions to specific needs is one of our strengths.

CSV Containment provides tailor-made solutions for pharmaceutical and fine chemical sectors in terms of containment. For more info: containment@csv-ls.com

CSV Containment provides tailor-made solutions for pharmaceutical and fine chemical sectors in terms of containment. For more info: containment@csv-ls.com