CSV Containment Unveils a Station Tailored for Powder Pump Equipment Charging & Transfer, Offering Superior Capacity & Contained Drum Handling.

Powder pumps are extensively employed in pharmaceutical and chemical industries, as well as areas like the food sector, for transporting substances from drums to reactors or other structures without compromising product integrity. Ensuring the product maintains its characteristics and quality while safeguarding worker health are pivotal goals in any production environment. CSV Containment fills this niche with a crucial piece born out of the continuous development of DIT® technology.

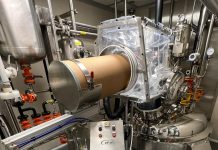

The station boasts a design aimed at optimizing space and managing workflow rapidly and securely. The lifter, integrated with the glove box, ensures compactness and versatility, allowing for the loading of drums with varying diameters. The chamber swiftly channels products to the hopper, where different vacuum transport solutions can be attached based on client needs. CSV Containment technicians collaborated with De Dietrich colleagues to enhance the user experience for those using powder transfer systems.

A Winning Combination.

The fusion of these two technologies, Drum Iris Station & Powder Pump, undeniably augments the production process, increasing speed and reducing the manual labor and operations required by workers.

The Powder Pump is a dense-phase pneumatic transfer system designed to transfer a wide range of solids in a safe and contained manner from various types of feed sources. Simple in design, construction and operation, the Powder Pump enables solids charging via a closed system, providing a dust-free environment. With proper solids analysis and testing, the Powder Pump is the ideal solution for transferring products of varying sizes and flow characteristics, even hazardous products. The Powder Pump system coupled with the DIT® system ensures that operators are kept safe and hazardous/toxic materials are dealt with appropriately. Depending on the pump’s power, it’s feasible to space the drum unloading zone using the DIT® station from the reactor or the desired end-point.

The optional Lump Breaker.

After the hopper has been cleared of material, the wip phase can be conveniently executed using the internal spray gun and an optional external tank for loading the washing fluid. Another intriguing option is the compact Lump Breaker produced by Officine Galesso, which can be positioned above the rotary valve to crush any potential material lumps before suction. The Lump Breaker is separated from the working chamber by a safety grid. For the station’s bag-out, the entire Flexilab product line by CSV Containment is available, from continuous liners to Twin Tie® closure systems, with a pneumatic tool available for tightening straps.

Main Features of the DIT® Glove Box:

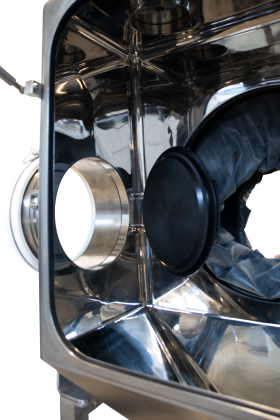

- Trapezoidal Chamber equipped with an openable front glass equipped with 2 EPDM gloves

- Double Drum Iris Technology for drums docking, manually operated or automatic (by pneumatic motors)

- DN 300 Continuous liner as waste bag out

- Pneumatically actuated drum tipper, mechanically integrated in the station, at its back and in front to the double iris

- Fully Automatic Drum Handling as optional

- Waste grooved side bag out grooved canister in continuous liner

- WIP PTFE Spray Gun connected via PFA or FEP flexible hose

- Trapezoidal conical shape in the bottom to address the powder to rotary valve (Lump Breaker as optional over the rotary valve)

- Pneumatic rotary valve as optional

- Twin Tie system kit made of a manual tighten tool, a cutter and a set of 100 Twin Tie

- Pneumatic tighten tool as optional

Main Features of the Powder Pump:

- Transfer using vacuum to maximize dust containment

- Ability to safely add products into pressurized or flammable atmospheres

- Filter Sock rated for 99.9% efficiency @ 1-micron particle size

- Secondary port for cleaning or level-detection

- Tool-less access to filter element to enable easy changeout

- All components are anti-static/conductive and bonded for grounding

- Sanitary design for pharmaceutical applications

CSV Containment provides tailor-made solutions for pharmaceutical and fine chemical sectors in terms of containment. For more info: containment@csv-ls.com