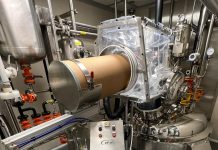

The range of flexible weighing and dispensing isolators by CSV Containment ensures containment levels up to OEB 5 and can be equipped with tools for controlling the internal atmosphere to operate under negative pressure, controlled humidity, and/or inert environment.

Each of the flexible weighing and dispensing isolators made by CSV Containment is customizable according to the measurements and requirements of the customer. In this specific case, the need to work in a controlled environment to preserve the health of operators and the product has led to the creation of a hybrid pressure control system. In fact, the combination of valves and differential pressure transmitters allows the operator, through the accessible control system via a dedicated HMI, to adjust the pressure and monitor its regular behavior or recognize and communicate any anomalies, also considering the products treated inside the chamber.

Filtered aspiration is carried out through a variable speed fan on the ceiling of the isolator, regulated by a digital inverter from the control system. The same applies to the inlet air supply if it needs to be connected to an existing system or to compressed air or nitrogen. In any case, the system can take air from the environment, always through HEPA filters.

Bag out and unloading.

The bag out and unloading operations are ensured by the proven CSV Containment systems equipped with canisters with a bag tightening ring with an inflatable seal to secure the liners and facilitate the operations. The liners, of different diameters and lengths, are all Made in Italy products, and the new Twin Tie® closure straps also represent an excellence made by CSV Containment.

Once the weighing operations are performed inside the chamber, the product is discharged into the liners through a versatile coupling, created with Eziflow cassettes, which also allows the use of specific bags equipped with the passive component of the mentioned cassette. To ensure the passage of cables from the internal balance to the chamber, the flexible weighing and dispensing isolators by CSV Containment are equipped with special iris pass-through cable device, directly welded to the flexible material and adaptable to different cable diameters.

Key features:

- Pre chamber with 1 front glove

- Main chamber with 2 front gloves

- Mobile and self standing thanks to the Plug and Play utilities connections

- Pivotal antistatic wheels equipped with brakes

- Glove box filters (HEPA H14)

- Inlet Filtration (HEPA H14)

- Spray gun for cleaning

- 8” grooved side bag out steel-made canister hosting a 14” diameter continuous liner

- Eziflow interface for product offloading bottom

- 4” grooved canister clamp ends connected to a passive cassette and hosting a 10m long and 8” diameter continuous liner for product unloading

- Swinging inflatable seal ring to be free in a vertical position during liner pack change or hooked in a horizontal position during unloading

- Iris wires/cables pass-through device

- Steel-made variable speed fan

- PLC to control the process

- Human Interface Machine (HMI) to supervise and control equipment process and activities

- Optional Mettler Toledo scale

CSV Containment provides tailor-made solutions for pharmaceutical and fine chemical sectors in terms of containment. For more info: containment@csv-ls.com