After the adjustment imposed by Annex1, also transferring vials safely has required the study of new solutions, especially when transiting Grade B areas.

Imagine having to deal with transferring vials safely from Grade A environments, passing through a Grade B area, and performing continuous particle monitoring in a protected, mobile structure.

Now all this is possible thanks to the special LAF trolleys born of AM Instruments’ experience and CSV Containment’s in-depth knowledge of risk assessment. The so-called Cart2Count® is an ISO Class 5 material transfer system equipped with continuous monitoring. The Cart2Count® ensures the transfer of vials in complete safety, allowing crossing even grade B areas, without the need for an electrical supply, having a battery life of up to one hour.

Cart2Count® in action.

A typical example of LAF trolley applications is the transfer of partially stoppered vials from the filling line to freeze dryers and from them to the vial-capping machine.

Actually, plant layout design is often imposed by the need to reduce construction and maintenance costs for classified areas. For this reason, but also other needs, vial filling lines may be located far from freeze dryers.

Products that are to be freeze-dried may pass through lower classification zones and the recent regulations on the subject, provided by Annex1, require greater attention and the search for practical and innovative solutions. Cart2Count® makes it possible to safely accommodate vials in special trays, transporting more than a thousand at a time. Each trolley has six or seven shelves on which to house the material, but the internal configuration is customizable according to the client’s needs.

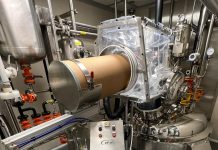

LAF trolley equipped with HEPA filter.

Inside the trolley, the air is drawn from the environment through pre-filters located at the sides, filtered by the HEPA filter, forced horizontally into the tray working area, and finally expelled by an extraction grille and recirculated within the trolley itself.

The recovery zone is designed so that air recirculates in both the lower and upper parts of the trolley. This process keeps transport safe even in Grade B areas, shielding the material from turbulence and possible quality changes. Continuous monitoring through a particle counter, installed on each Cart2Count® trolley, is an additional safeguard, even against potential deviations that might be found during inspections.

The following are some features of the LAF Cart2Count® trolley:

- Ergonomic and dedicated design

- Pivoting and braked wheels

- Control HMI

- On-board continuous particle counter

- Sealed doors and recirculating airflow

- Sampling probe in the “worst case” position near the air recovery zone

- Adherence to data integrity in monitoring data management

- Complete control of process parameters through an integrated control panel

- Structure dimensions and internal layout customizable upon request

CSV Containment provides tailor-made solutions for pharmaceutical and fine chemical sectors in terms of containment. For more info: containment@csv-ls.com