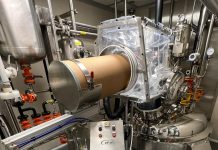

CSV Containment realized a vaccines filling isolator for liquid solutions to serve the pharma supply chain.

The new vaccines filling isolator is an effective and ergonomic tool to perform activities in the production process that require liquid dosage accuracy and safety.

The structure made of Aisi 316L stainless steel is intended and designed to contain liquid filling operations in small glass containers, inside a glove box suitably equipped to manage the process under inert conditions.

The filling isolator for liquid vaccine solutions consists of a pre-chamber, placed to the left side and equipped with a glove for handling operations, and a main work chamber, which is equipped with handling gloves too.

Isolator for liquid vaccine solutions – characteristics:

Pre-chamber:

- EPDM inflatable sealing gaskets

- Ambidextrous glove made of neoprene or conductive EPDM

- ATEX LED lighting unit

- Worktop provided with a decontamination liquid waste outlet connected to that of the work chamber

- Flow shut-off valve suitable for an easy decontamination and cleaning

- Roller conveyor to facilitate the product/containers handling and transfer

Work chamber:

- Roller conveyor for product/containers handling and transfer

- Stainless steel ATEX Rated Weighing scale positioned in the middle of the work chamber and connected with an ATEX indicator, a 17-key keyboard and a LCD (Atex) display externally installed.

- EPDM inflatable sealing gaskets

- Quick clamping system made of Aisi 316L stainless steel and opening at the top, counterbalanced with springs

- 2 ambidextrous glovesmade of neoprene or conductive EPDM

- ATEX LED lighting units

- PE500 Conductive Door separating the pre and the main chamber

- Worktop provided with a decontamination liquid waste outlet. It is equipped with a connection and a flow shut-off valve suitable for an easy decontamination and cleaning connectable to dedicated container or outlet

- Through the wall connection for liquid transfer from the upstream reactor (clamp connections) with an stopcock, a “T” junction and a tap for sample collection

- Safety locking wheels

- Upper wall with nitrogen inlet and outlet, with corresponding taps

- Inlet filtering unit, located outside, with H14 absolute incombustible filter, closed in an AISI 304 protection container with a shut-off and control flow valve (in manual mode with the valve)

- Safety filter unit, located outside at the exit, with H14 absolute incombustible filter, closed in an AISI 304 protection container with a shut-off and control flow valve (in manual mode with the valve)

- Centrifugal extractor at fixed speed, in accordance with ATEX standards for zone 2-22 (ATEX 3GD)

- Differential pressure indicators for controlling the operating de-pressure adjusted with manual valves during set-up and qualification phase

Other features:

The vaccines filling isolator is also equipped with an inertization plant for maintaining the defined conditions of depression. The pre-chamber and main chamber are both inerted under a flow of nitrogen.

The doors are opened and closed by manual activating and deactivating controls of the inflatable gaskets.

The management panel (control panel) complies with ATEX standards for Zone 2/22 – 3GD and is intended for the following drives:

- Extractor switch-on/off

- Light control

- Voltage presence signalling

- General alarm signalling

- Emergency button

- Main switch

CSV Containment is present in the pharmaceutical market and is focused on providing engineering, construction and validation solutions for the LifeScience world. For more information:containment@csv-ls.com