The new CSV Containment assembly workshop is a sign of quality for whoever wants excellence products made of selected raw materials, carefully manufactured and even tailor made.

CSV Life Science Group, after years of work and experience in the Pharma world, has decided to start a new assembly workshop for some of its products, given the necessity and desire to complete its services and become a partner capable of responding comprehensively to all its customers’ needs. Throughout the years, the constantly-growing divisions dedicated to containment and process plants have reached such a level of experience and professional expertise that CSV new workshop can now realize an increasingly advanced products and solutions. Research, development and quality control have become the keystones of all the Group’s new projects, and within a few years the first steps of own production have become well-established realities.

The new workshop is added to “FlexiLab“.

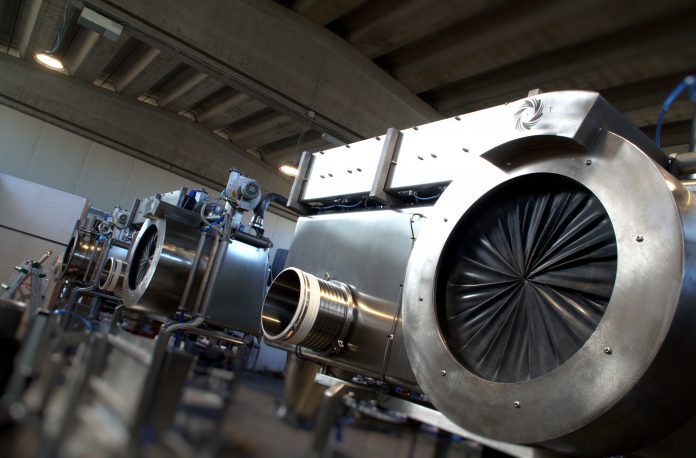

CSV Containment opens the new year with a new production site in Piedmont, close to the well-founded department for liners and tailor-made flexible isolators production. The assembly and finishing steel workshop strengthens the production of rigid isolator, whose first pieces for 2022 have already been prepared right there.

The DIT technology and all its application are especially given attention. An example of this care is the recent realization of a DIT version equipped with an encoder to allow the irises to fully automatically dock drums with different diameters. Moreover, leak test as well as cleaning, SMEPAC and validations are performed in the new Alessandria workshop, sometimes even on behalf of third parties. The workshop produces all the lifts and flexible isolator structures internally by itself in FlexiLab, the nearby ISO 8 department, which has been in operation for several years.

About 15 professionals are involved in the two Piedmont sites and they take care of both rigid and flexible isolators realizations as well as of a wide range of liners. In 2021 hundreds of flexible isolators were built and now more than 60 different kind of continuous liners can be produced depending on customers’ requirements. Thousands of metres of flexible material have been used for donut and folded liners, thanks to the collaboration and research with market-leading companies in order to assure the top-quality in terms of transparency, strength, flexibility and anti-staticity.

Teamwork.

All the staff employed on the two sites is always working in synergy and the constant entrance of new professional figures is a sign of the growing trend that has been affecting the Group’s containment division for some years now.

The work of CSV life Science Group is more and more oriented to the synergy between its several branches in order to meet more quickly and flexibly the requirements of the nowadays changing market and to offer innovative tailor-made solutions to each customer. With this mind, CSV Life Science Group wants to improve its own production and this is made possible by the collaboration of all its divisions, by the experience and quality of its collaborators and by the ability to face every project with a comprehensive approach to guarantee the best possible response.

CSV Containment is present in the pharmaceutical market and is focused on providing engineering, construction and validation solutions for the LifeScience world. For more information:containment@csv-ls.com