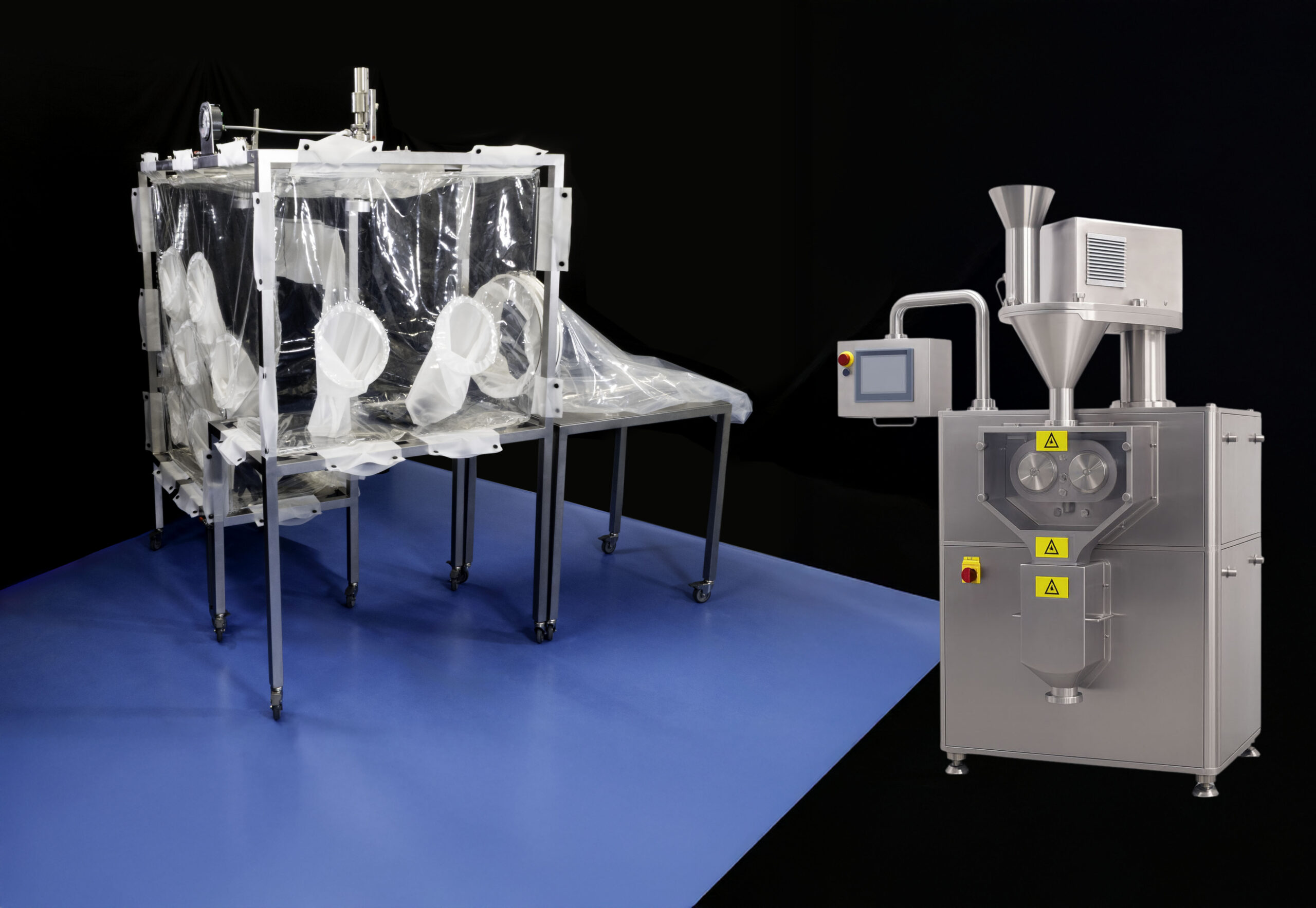

A dual containment solution for safe and efficient drum handling.

The new high-capacity Dual Containment glove box is designed to manage powder discharge operations with enhanced protection, extended autonomy, and improved ergonomics. Developed for applications requiring stringent OEB-level containment, this upgraded structure accommodates larger drums, longer continuous liners and ensures full process protection during every phase of powder handling.

In addition to increasing operator and product safety, the Dual Containment configuration also provides a GMP-relevant advantage: the replacement or installation of the continuous liner is performed inside a closed, controlled environment. This prevents exposure of the process during liner changeover, addressing a common regulatory concern in unclassified backgrounds.

For this reason, regulators and auditors increasingly request a secondary controlled barrier to ensure that liner operations occur in a contained, GMP-compatible area.

Engineered around larger drums.

To support higher processing volumes, the glove box is now built with increased internal capacity. This chamber allows operators to work with larger drums and longer liners, offering greater autonomy during bag-out phases and powder filling operations.

Two additional lateral gloves improve the maneuverability, making liner separation easier. Internal supports are also provided to hold the manual tensioner and Twin Tie® clamps, ensuring that all tools are easily accessible during the workflow.

An internal roller conveyor, equipped with a drum-blocking system, facilitates smooth and safe drum loading and unloading. For external handling, a dedicated mobile drum trolley with its own roller surface is available on request.

Designed to Ensure Full GMP Compliance.

Dual Containment answers a key GMP requirement: although the discharge circuit is already closed by design, regulators often highlight that liner replacement in an open, unclassified background exposes the process.

The Dual Containment glove box is designed to offer:

- GMP-relevant process protection, even when the surrounding area is not classified

- Continuous liner mounted internally at the discharge point

- Inflatable-seal collar for dust-tight liner locking and controlled unrolling

- Integrated cleaning tools, including spray gun and drainage point

- Internal support for manual or pneumatic tensioner and Twin Tie® clamps

- External pneumatic control panel

Thanks to the additional glove ports, operators can comfortably manage liner cutting, sealing and removal while maintaining full containment performance. With greater operational space, enhanced autonomy, and an upgraded ergonomics layout, the Dual Containment glove box offers a reliable and safe solution for powder discharge operations involving larger drums and more demanding processes. It ensures maximum protection for the operator, the product, and the environment, delivering true high-capacity containment performance.

Main Features of the Dual Containment Glove Box:

- AISI 316 stainless steel chamber with enlarged capacity

- Large front glass panel door with inflatable seal and ergonomic gloves

- Additional lateral gloves for improved operability

- Internal roller conveyor with drum-locking system

- External drum trolley with rollers (optional)

- Actuated Butterfly valve for the inlet and the outlet line

- Valve for the depression maintenance

- Canister for Continuous liner mounted inside the chamber

- Inflatable-seal anti dust collar system and carter

- 2 push-push HEPA filters for the outlet

- 1 Glove Box HEPA filter for the inlet

- Cleaning spray gun

- Draining point on the bottom

- Twin Tie® kit (optional)

CSV Containment provides tailor-made solutions for pharmaceutical and fine chemical sectors in terms of containment. For more info: containment@csv-ls.com