Expanding our Disposable Containment Systems Production Capacity with a new area dedicated to flexible manufacturing.

The constant growth in demand for disposable containment devices has pushed us to develop new solutions. At CSV Containment, we have expanded our laboratory for processing flexible materials, the “Flexilab”, and have started developing new flexible isolators designed for the BSL (Biosafety Level) sector.

A new ISO8 environment.

A new building has been operational at CSV Containment, the Piedmont company part of CSV Life Science Group, for several months. This new building is located alongside the existing areas where we produce and assemble glove bags and glove boxes. Inside this building, we have created a brand-new cleanroom, dedicated to disposable products — primarily donut and folded liners. Cutting machines, welding stations, testing areas, and spacious warehouses form a setup designed to scale up production and enhance product quality, while also opening the way to new solutions.

The challenges that pharmaceutical companies face on a daily basis call for responses that are both reliable and flexible. Balancing proven methods with openness to innovation, continuity with the ability to evolve, at CSV Containment we provide tailored answers for every need — starting with the supply of custom-made samples for testing.

Our historic flexible material processing laboratory, the Flexilab, has expanded its production capacity to include new types of flexible isolators. With continuous liner production now relocated, the entire Flexilab area can focus on developing new solutions, such as laboratory glove bags, designed to meet BSL standards.

Biosafety Isolators.

Recently launched on the market in predefined configurations — though still open to customization — the benchtop instant isolators are gaining recognition for their ease of use and the option of being fully disposable. Some models are equipped with gloves integrated directly into the isolator and made from the same material, allowing the entire unit to be disposed of immediately after use while preserving the frame. The isolators are assembled with practical snap buttons, making it possible to mount or remove them from the frame in just a few minutes. The frames themselves, built with an interlocking system, can be disassembled and conveniently transported in the supplied carrying bag.

For PU isolators equipped with matted sleeves and butyl gloves, once the internal cleaning process is completed with a wipe, the isolator can be collapsed, stored, and reused with the same product. Each isolator is fitted with a large gas-tight zipper to allow the introduction of balances or laboratory instruments, while power cables can be managed through practical cable glands with iris diaphragms.

In addition to serving as reliable containment measures for BSL laboratories, CSV Containment’s benchtop isolators provide an excellent solution for research, analysis, or decontamination activities that require agile and user-friendly systems. And for more advanced containment needs, including higher BSL levels, CSV Containment also designs and manufactures a wide range of pressure-controlled solutions, both flexible and rigid.

Ongoing development.

Ongoing development.

Following the introduction of our first continuous liners, we have focused our efforts on expanding CSV Containment product range. From Donut to Folded liners, we have responded to our customer needs not only in terms of diameter, thickness, length, and color variety, but also in terms of quality. In addition to offering our own selection of films, we can also work with films supplied directly by customers.

What does this mean? It means that if a customer has a trusted, qualified, and tested material they wish to use to quickly produce dedicated liner solutions, at CSV Containment we can use them. This approach allows lead times to be shortened while ensuring an additional level of safety for those who require such products.

Is this an exception, or can it be extended to other items? Starting from specific customer requests — and thanks to the capabilities offered by the new facility — we have applied the same concept to Disposable Bags.

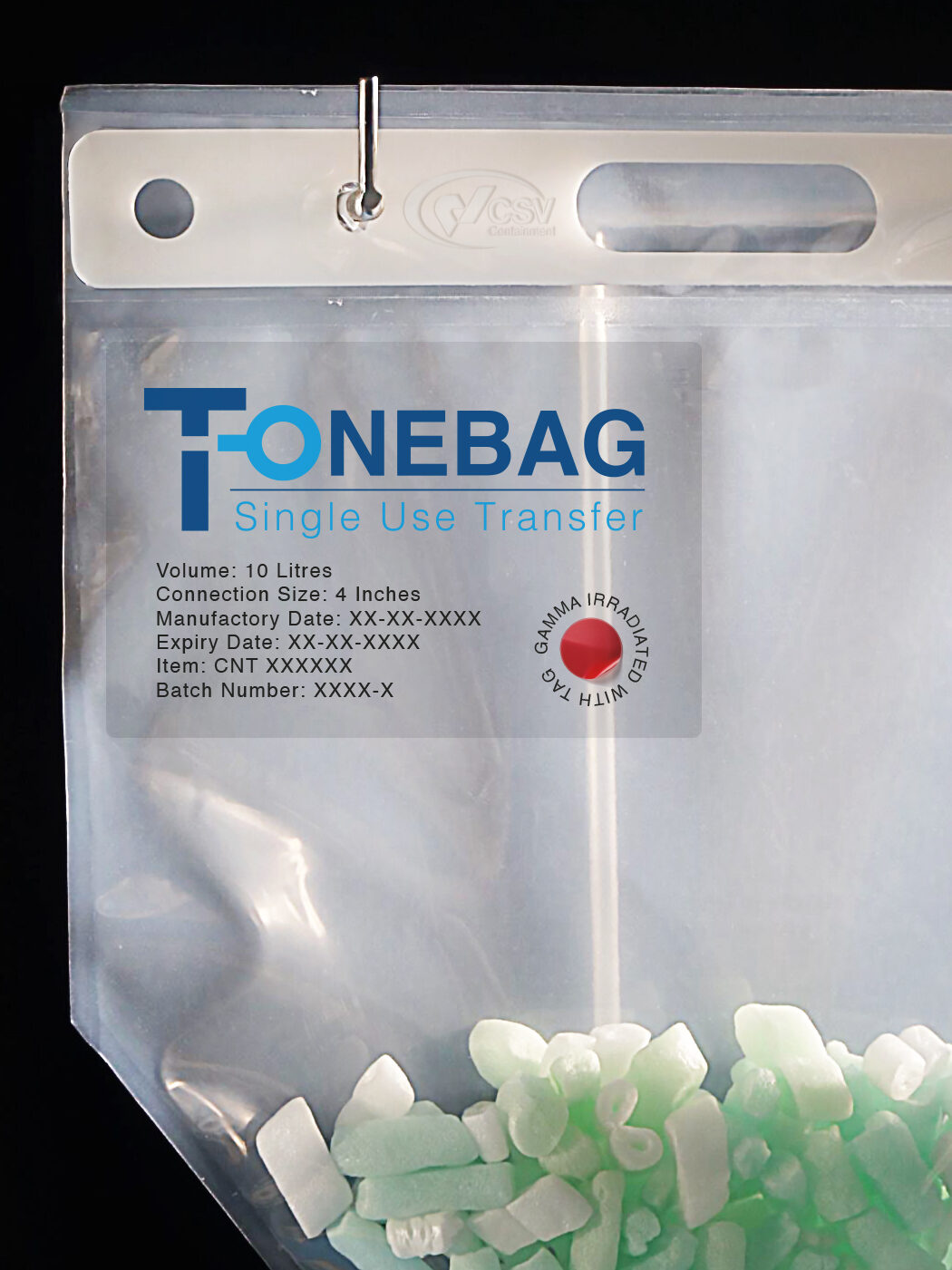

T-ONEBAG is the single-use transfer bag designed for organizations that require a product made from materials with precise quality specifications.

T-ONEBAG is the single-use transfer bag designed for organizations that require a product made from materials with precise quality specifications.

The first 10L version is about to enter the market, equipped with a 4” clamp for connection with the main valves and a practical handle for transport. A variant with added barb connectors, allowing tubing for liquid transfer, is also planned.

An expanding product range.

We have taken a decisive step forward to reach new goals and serve our clients with even greater precision and dedication. CSV Containment product portfolio has been expanding steadily, with recent years seeing the introduction of the proprietary Twin Tie closure systems for liners and sleeves, along with the corresponding tensioning tools. To the pneumatic version, a manual one has recently been added, completing a line that meets every customer requirement.

Still within the disposable segment, we also manufacture X-ONEPONCHO, an innovative over-garment device combining an LDPE hood with a Tyvek suit.

CSV Containment provides tailor-made solutions for pharmaceutical and fine chemical sectors in terms of containment. For more info: containment@csv-ls.com