Drum pneumatic powder transfer containment via the new Automatic Bag In Bag Out interface.

CSV Containment has filed a patent application for an automatic interface designed to make coupling and powder transfer from drums via Bag In Bag Out safer, cleaner, and more efficient.

Technique and technology.

The now widespread and well-established Bag In Bag Out procedure is traditionally performed manually and requires a high level of care and attention from operators, as well as the use of single-use devices (O-rings and bags) to avoid exposure to powders.

Introducing and handling powders within a confined environment is a daily activity for many operators in the pharmaceutical field and beyond. In most cases, these operations rely heavily on the operator’s technical skills. However, this does not mean that solutions cannot be developed to simplify certain steps, increase safety, and improve operational speed.

CSV Containment’s technicians face these challenges every day, working side by side with customers to develop tailor-made solutions. The sharing of specific production requirements, combined with the creative expertise of our containment specialists, leads to solutions designed to be brought to a broader audience.

The DIT® standard.

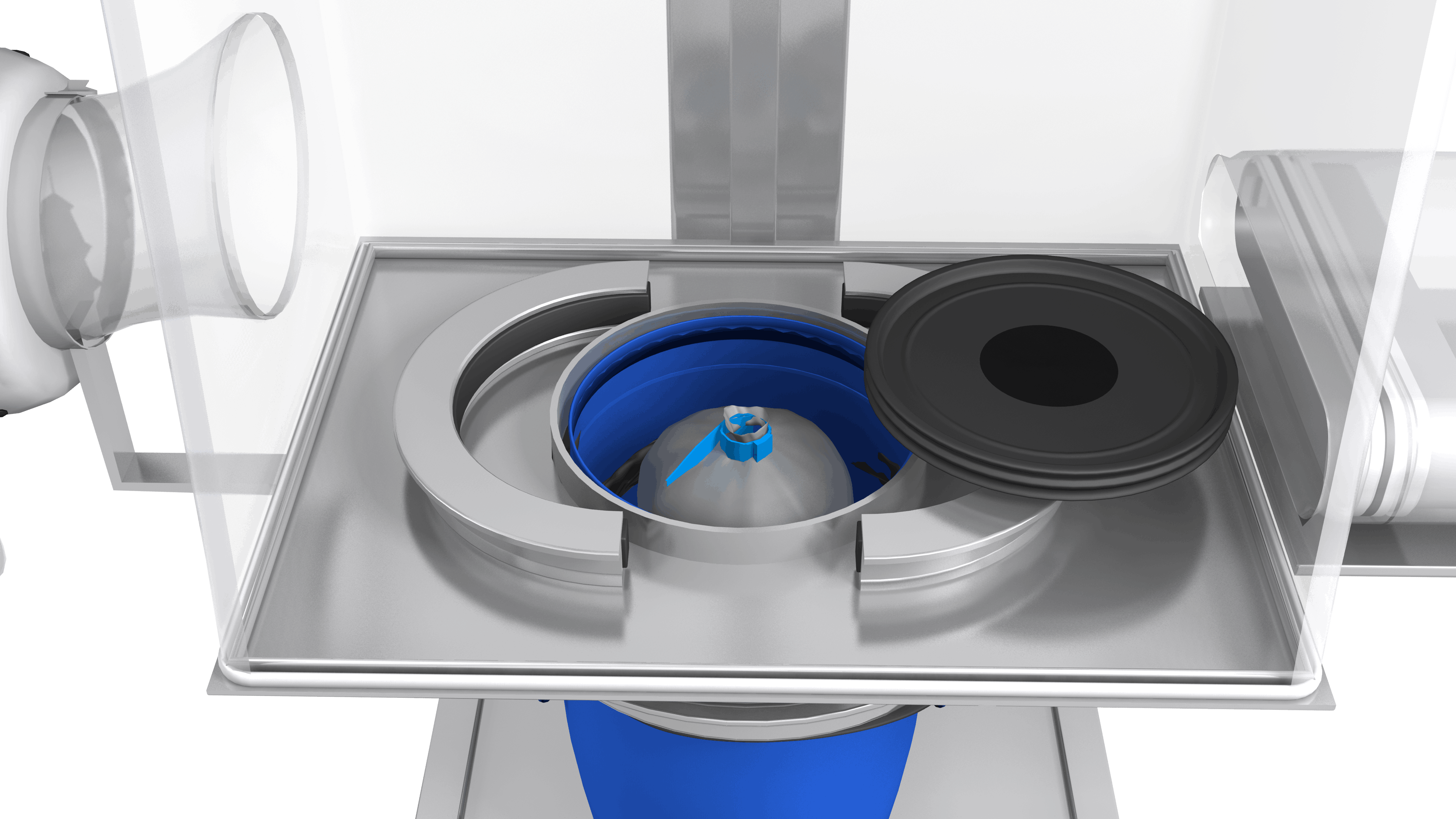

From an innovative concept to an established standard, in just a few years DIT® technology has been successfully applied in numerous contexts. Beyond glove boxes and glove bags for reactor loading, the patented Drum Iris Technology has also proven effective in flexible powder transfer stations. Its ability to accommodate drums of different diameters makes this solution virtually universal, significantly simplifying operators’ work.

A new step forward in safety.

At CSV Containment, operator safety and the pursuit of greater production efficiency are the driving forces behind innovation. Experience, customer listening, and continuous research push our teams to go further and turn ideas into concrete solutions that improve workflow. This approach led to the development of the patented Automatic Bag In Bag Out interface.

At CSV Containment, operator safety and the pursuit of greater production efficiency are the driving forces behind innovation. Experience, customer listening, and continuous research push our teams to go further and turn ideas into concrete solutions that improve workflow. This approach led to the development of the patented Automatic Bag In Bag Out interface.

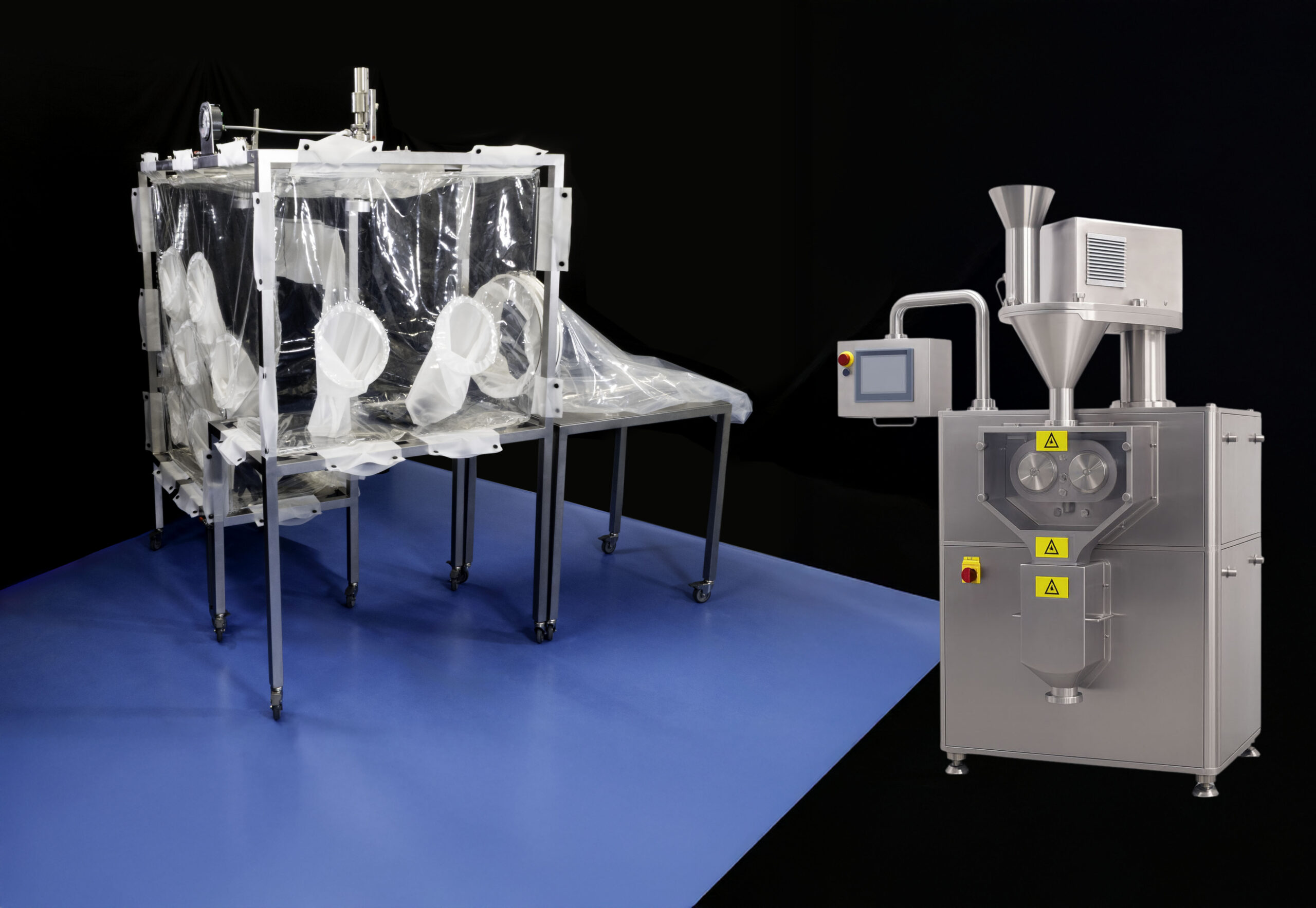

The Automatic BIBO Interface is an innovative pneumatic device capable of creating a double protective barrier between the isolation chamber and the external environment/operator. This dual safety barrier is maintained during the most critical phases of drum transfer, both insertion and extraction.

The system combines a DIT® iris diaphragm, which tightly grips the drum body, with a mechanism that secures the external bag to a concentric ring inside the isolation chamber. This operation prevents contamination of external drum surfaces and avoids exposing the internal atmosphere and surfaces of the isolation chamber to the outside environment and, consequently, to the operator.

The result is a clean procedure that allows powders contained within the bags to be handled without contaminating the drums, reducing risks for operators and, thanks to automation, increasing operational and production efficiency.

Disposable and definitive.

Two seemingly contrasting concepts, yet stations equipped with this technology become the definitive solution for safe and efficient Bag In Bag Out operations in confined environments—whether based on disposable flexible technology or traditional stainless-steel isolation systems.

All our isolators are designed and manufactured to meet specific customer requirements and integrate perfectly with the technological solutions incorporated into each station.

The Bag In Bag Out Automatic Interface can be applied in various contexts, such as the containment of drum-to-process powder transfer operations using pneumatic or vacuum systems. In this configuration, the structure includes multiple canisters for bag-in of accessories, bag-out of waste, and clean removal of drum lids. A convenient tilting support has also been added to easily store lids in a side sleeve and safely separate them.

Relieved and Lifted.

Not only are operators relieved from critical handling steps, but the structure itself supports operations by lifting pneumatically to allow easy drum replacement. This also enables height adjustment to facilitate the insertion of powder transfer lances, allowing the optimal working position to be set from the start.

Innovation never stops. This and other derived versions of the Automatic BIBO Interface will soon be available. Our containment experts are at your disposal to present this new solution developed by CSV Containment. Contact us and keep following our blog to stay updated on the next steps.

CSV Containment provides tailor-made solutions for pharmaceutical and fine chemical sectors in terms of containment. For more info: containment@csv-ls.com