The profile makes the difference, even when containing a pharmaceutical Roller Compactor.

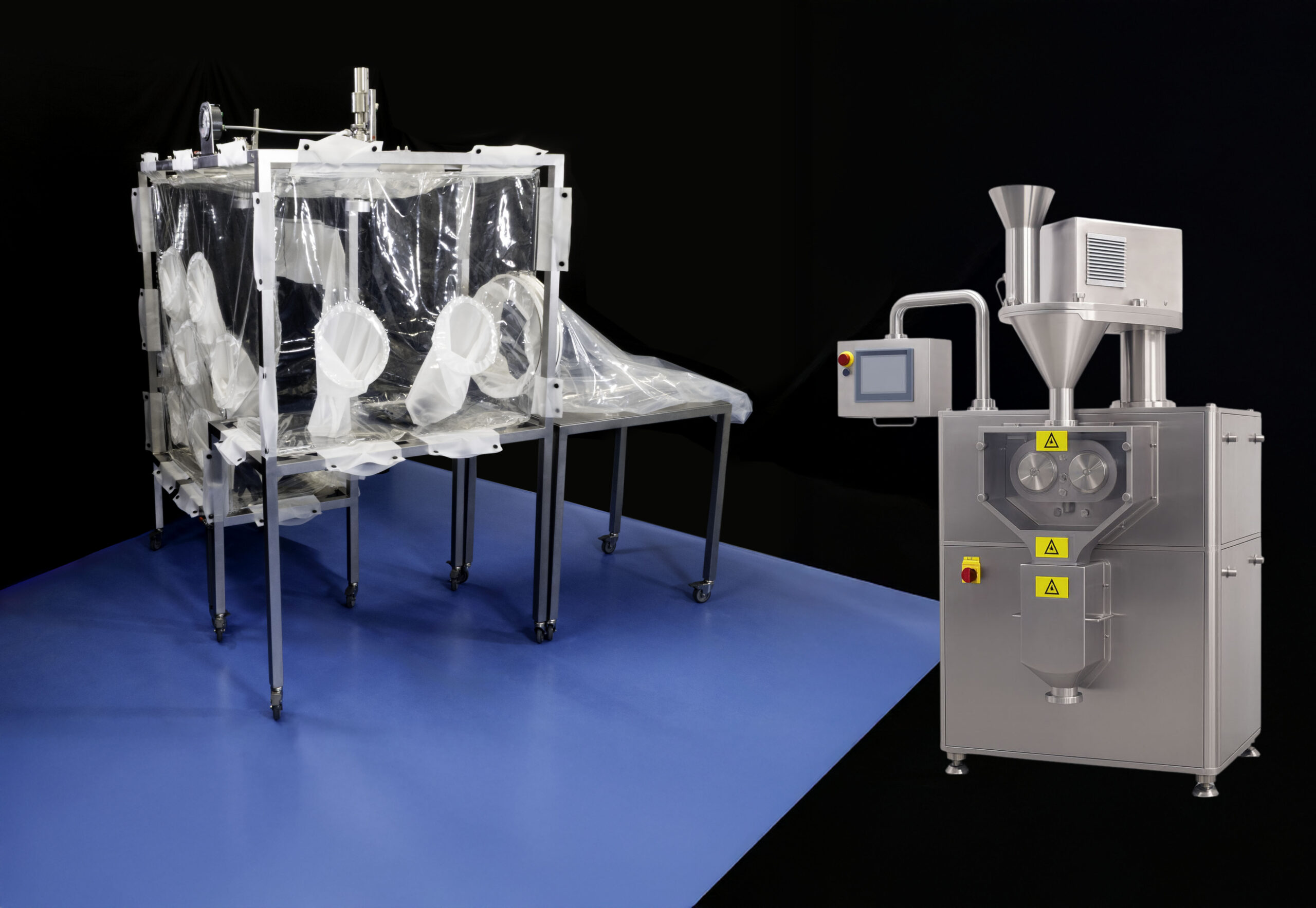

In a recent Roller Compactor upgrade project, we used a flexible isolator with already tested custom solutions, an approach that has now become a standard practice for us. The choice of a dedicated glove bag proved to be the ideal solution: easy to implement and not overly invasive.

Working in containment already involves more complex procedures, so for us it is essential that, in addition to safety, practicality is equally important. After gathering all the client’s requirements, we take care to understand how operators interact with the machine.

Improving the working experience.

For our designers, it is essential that the operators’ experience be both safe and comfortable. They must have an adequate number of gloves available to reach the equipment’s working areas and to properly perform maintenance. When handling bags or introducing tools, containers, or bags, appropriate work surfaces and bag-in/bag-out solutions must be included in the containment structure. A structure that does not necessarily need to completely enclose the roller compactor. To avoid developing an excessively large isolator, CSV Containment has been using a special profile around machines of this type for some time now.

Profile in the spotlight.

Developing a custom steel profile to ensure the isolator encompasses only the essential parts of the machine, and not all of them, is a solution that offers multiple advantages. The isolator, once secured to the profile via a U-grip gasket, allows for a less invasive and more practical approach. At the same time, replacing the isolator sleeves becomes less costly. The sleeves are therefore open on one side and secured to the frame previously installed on the machine. The profiles are positioned and secured with FDA-compliant adhesive and sealing materials. The installations are custom-made for the equipment, and the sleeves are secured during installation with special U-shaped gaskets capable of firmly anchoring the film to the frame.

Needs change, clothes change.

The transparent “clothe” of our isolators, if we may call it that, can evolve to meet the client’s specific developments and requests. After the initial supply, modifications can be made based on operator experience: adding or removing gloves, adjusting sleeve lengths, incorporating cable, or installing additional CPC connections for water hoses. Even the isolator film type can be customized in consultation with the client, along with sleeves and liners tailored to specific requirements.

CSV Containment manufactures the frames, sleeves, liners, and separation systems in-house. Our isolators can also be configured to operate under negative pressure and equipped with filters, cleaning accessories, and any other features the client requires.

If you don’t find your specific case on our blog, contact us—we’d love to add a new article inspired by your needs!

CSV Containment provides tailor-made solutions for pharmaceutical and fine chemical sectors in terms of containment. For more info: containment@csv-ls.com