HPAPI R&D environments are areas that require equal or greater attention than that given to production.

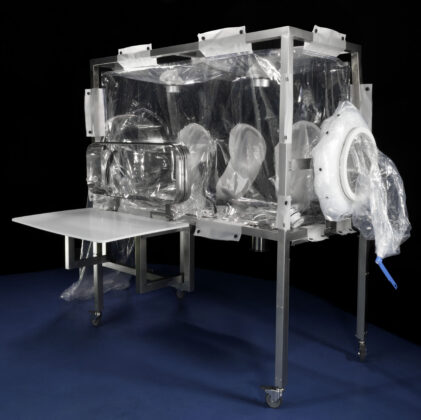

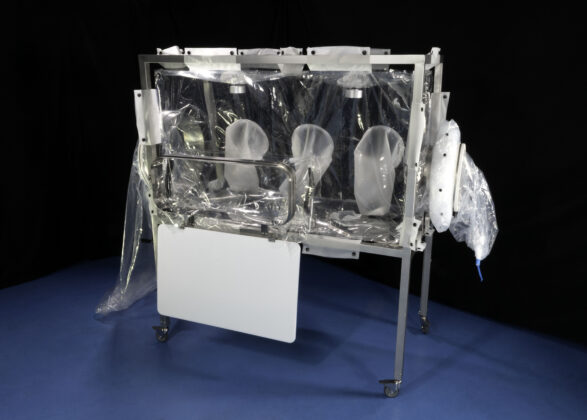

When we talk about HPAPI R&D labs, we are referring to dynamic, evolving, and flexible environments, just like the solution that CSV Containment has designed for these types of activities. With a lower budget than rigid isolators, flexible technology can also meet the safety requirements for handling HPAPI in research and development environments.

When we talk about HPAPI R&D labs, we are referring to dynamic, evolving, and flexible environments, just like the solution that CSV Containment has designed for these types of activities. With a lower budget than rigid isolators, flexible technology can also meet the safety requirements for handling HPAPI in research and development environments.

All necessary measures.

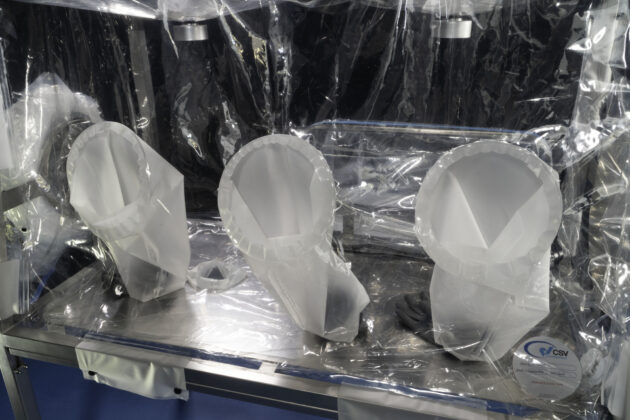

An isolator placed in HPAPI R&D environments must guarantee safety measures, facilitate the work of those who need to measure, dose, and weigh, and, finally, adapt to the existing spaces. This last point is our strength: working to measure and satisfy the customer’s requests as much as possible. Chamber dimensions, glove position, shape, and size of bag-in and bag-out ports. Another dimension we work on is height. For some time now, our isolators have been equipped with a telescopic mechanism. Hydraulic pistons, operated manually or by an electric motor, can raise the work surface from 90 to 130 cm in height. Height adjustment not only allows operators to find the most comfortable position for working with gloves but also facilitates connections with containment accessories.

Being connected.

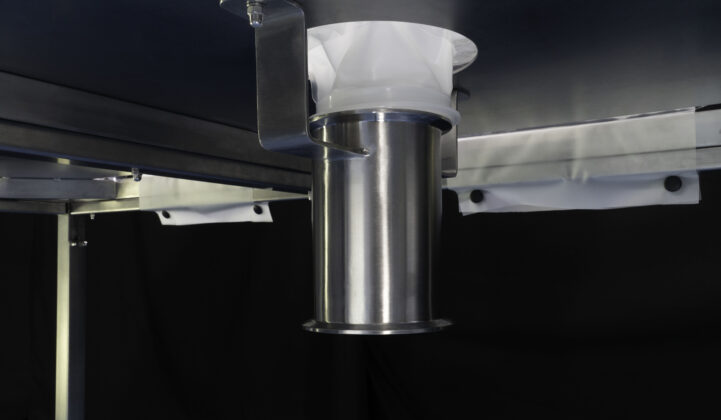

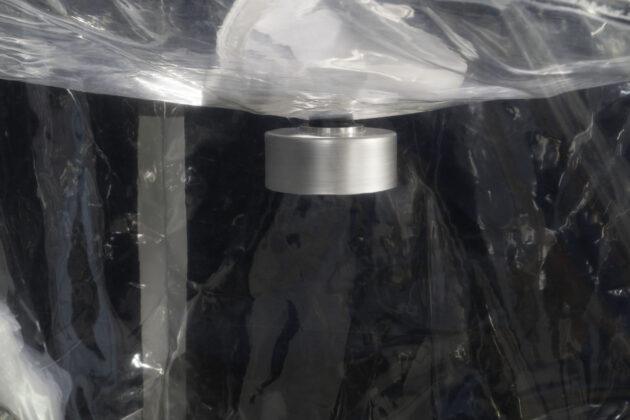

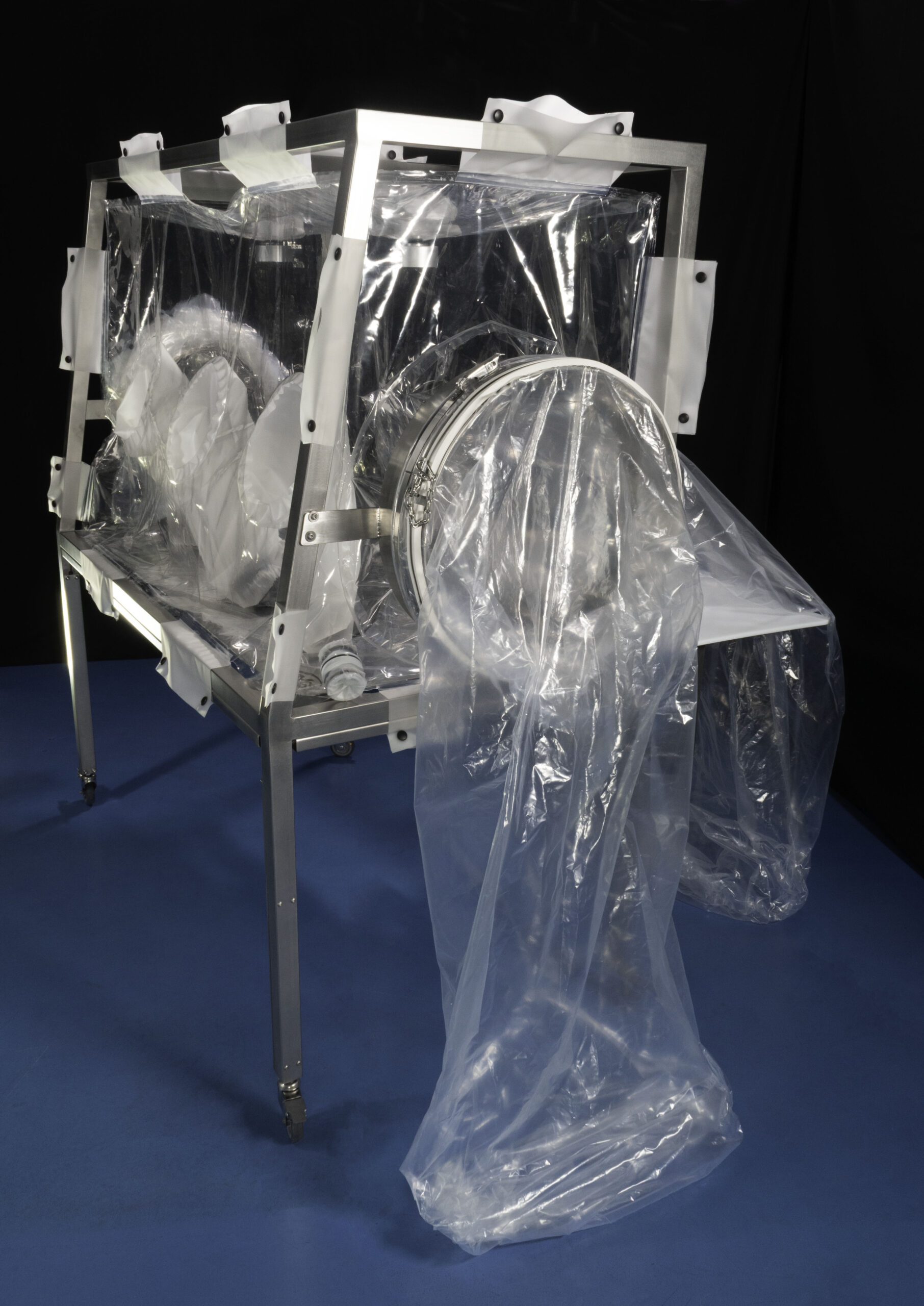

Work in the glove box does not begin and end inside the chamber but is part of a process. In addition to the BIBO lines present, being able to connect to a valve is essential. For this reason, the isolator frame is equipped with a clamp connection to interface with containment valves, for example. The valves allow dust or liquids (such as drainage for the washing phase, for example) to be discharged into bags or bottles.

Of course, flexible isolators can be equipped with CPC connectors to bring water inside and fitted with mini spray guns or vaporisers to facilitate chamber cleaning.

If instruments need to be brought inside the chamber and connected to the outside for power, our practical cable pass-through can be mounted directly on the walls.

Support.

We provide you support, but also supports. Depending on the customer’s needs, customised supports can be built to extend the working surface outside the isolator. A reclining table, for example, can help in the material entry or exit phases through customised sleeves. Supports for liners and canisters can also be customised. The addition of a collar with an inflatable seal, either manual or automatic, allows the liners to be locked in place and acts as an anti-dust barrier. Finally, to complete the offer, CSV Containment also provides support in terms of services. One of the most requested is the SMEPAC test, an activity in which our containment teams have extensive experience.

CSV Containment provides tailor-made solutions for pharmaceutical and fine chemical sectors in terms of containment. For more info: containment@csv-ls.com