Beyond Gravity: The Advantages of Reactor Loading from an Upper Level.

There are situations where, for various reasons, reactor loading must be performed using alternative methods. CSV Containment is able to evaluate the most suitable solution for your specific needs and implement it — as in the case of these configurations, all coming straight from above — quite literally this time.

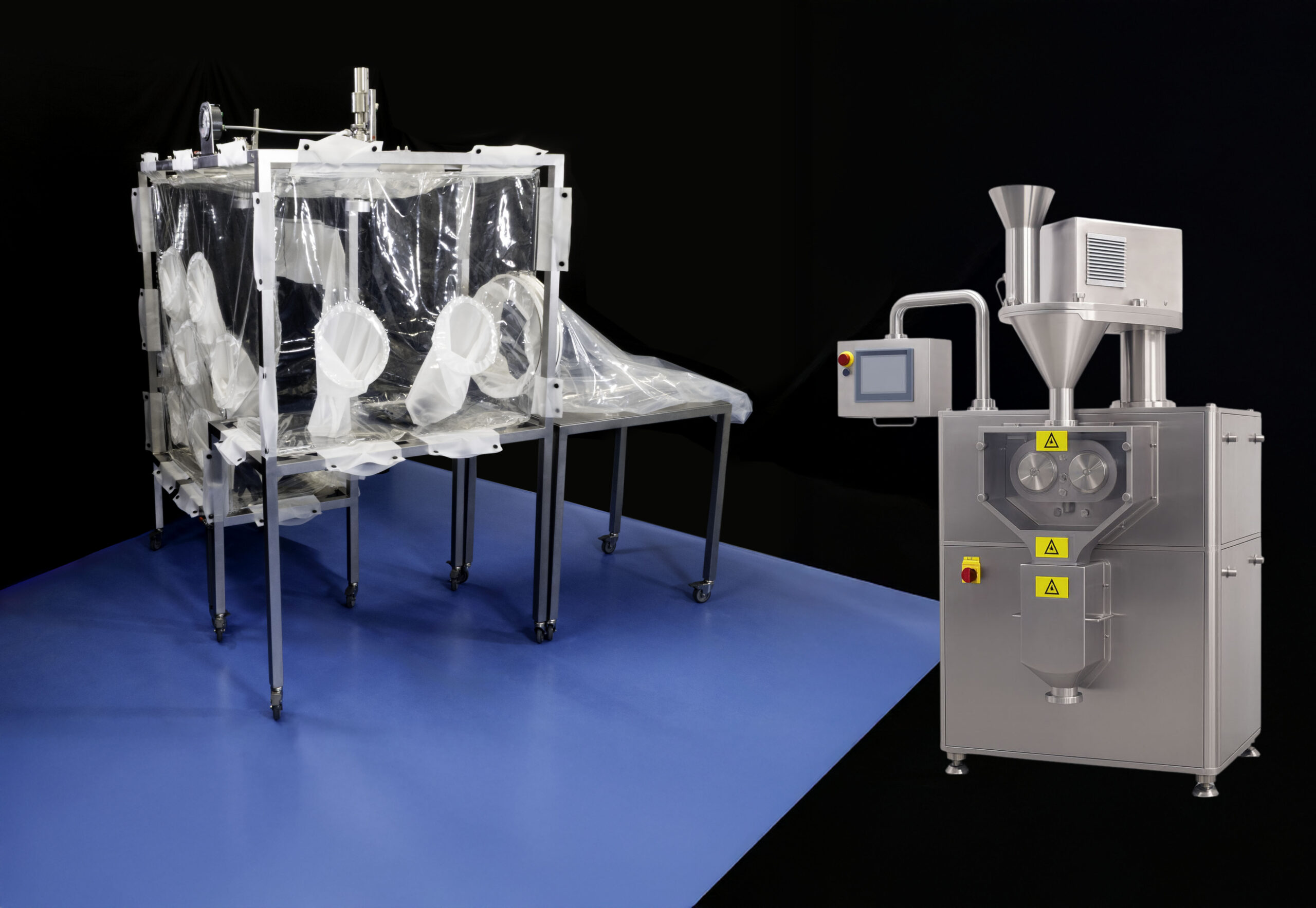

Working from the upper floor is sometimes the ideal solution. What might initially seem like a more complex setup can actually be driven by considerations such as space optimization, ease of operation, ergonomics, or other practical factors. Reactors are not always located in easily accessible or spacious environments. Barrel handling and product transfer might be more conveniently performed elsewhere, but the key challenge remains: how do you connect a glove box to a reactor if they are located on different levels?

Pumping or Dropping — That Is the Question.

Lifting the material up to the reactor requires a system capable of conveying powders — typically via pneumatic transfer — in a fast and safe manner. Between the charging station and the reactor, a pump could be integrated, but this is not always feasible. Moreover, pumps require more maintenance, increased safety checks, and additional energy consumption. Taking advantage of gravity for material transfer is undoubtedly simpler and faster, yet even this approach must account for safety measures and overall plant layout.

CSV Containment’s experienced engineers study and assess the entire process, managing the custom connection setup, glove box design, and — upon request — the integration of actuated valves to control the material flow.

Consent Is Always Required.

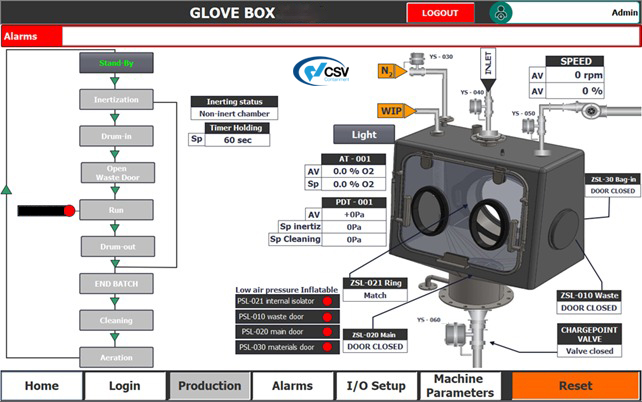

It’s not just about customer approval — the control systems must give their consent too. Reactor loading projects are fully managed — from the upstream isolator to the reactor’s connected piping.

In cases where pneumatic valves are used and actuated based on signals from the distributed control system (DCS), our technicians handle all related hardware and software integration.

CSV Containment’s programmers are experienced in interfacing with major DCS platforms on the market, including Siemens, Rockwell, Emerson, and ABB, among others.

Drop Tubes and Process Separation.

No need for vacuum or pressure — just free fall and valves designed to intercept and release material at the right moment. This makes it possible to create true “gravity chutes” between floors, allowing the drum loading area to remain completely separate from the reactor room.

If at the upper level, drums are handled with ease using one of our charging stations equipped with integrated lifters, meanwhile, at the lower level, the product reaches the reactor safely and efficiently. The workflow remains continuous and streamlined — ideal for high-throughput environments particularly for facilities with substantial production capacity.

As each system is tailor-made, it fits seamlessly into the existing plant layout, avoiding the need for costly structural modifications. Additionally, it ensures clear process separation and improved cleanliness throughout the production environment.

CSV Containment provides tailor-made solutions for pharmaceutical and fine chemical sectors in terms of containment. For more info: containment@csv-ls.com