In chemical and pharma processes, operators’ and products’ safety is becoming increasingly central. That is why a drum liquid transfer containment station is one of the tools that can make a difference.

A drum liquid transfer containment station aims at containing the opening, liquid transferring, or liquid sampling phases and the closing phase while assuring the highest level of products, samples, operators, and processes protection.

The transferring phase, as well as the sampling one, is a delicate phase and the scope of our work is to reduce the risk of contamination while ensuring clients both clean and safe processes and representative samples.

CSV Containment can indeed realize custom-made containment systems suitable for any kind of environment depending on production needs.

A problem while working and processing liquids is the chance they can emanate toxic or smelly fumes. Having a containment station. In this case too, having a containment station to carry out the processing is a step forward in ensuring proper safety conditions for operators.

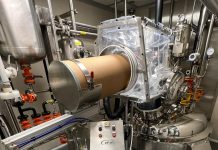

The drum liquid transfer containment station has been realized to host drums of different sizes, to facilitate their sliding with a practical roller conveyor equipped with a dual locking system of both the station and the drum. In addition, thanks to properly equipped walls, in this station all kinds of devices to bring the products to the reactors/tanks can be used.

Decontamination.

Another advantage of the station concerns drum decontamination, achieved thanks to specific tools and spaces. For instance, to contain liquid accidental flow, a collation tank has been created with a capacity equal to the maximum volume of the drum in use and the height of the door above the safety collection level. The glass walls are also designed to allow the greatest possible visibility and thus facilitate operations.

The station is entirely made of AISI316 steel and is equipped with:

- Slightly inclined upper front, to improve ergonomics, equipped with 5+5 mm thick safety glass

- 2 black conductive EPDM gloves on conductive plastic flanges.

- A manually-operated roller conveyor is positioned between the outside and the inside chamber base. It consists of steel rollers suited to the diameter of the drums, equipped with a foot pedal mechanism for locking the trolley on the station and the drum on the trolley.

- A flange connected to the departmental venting system or any other suction and abatement device.

- A PTFE spray gun with a PFA or FEP spiral hose, useful for washing the chamber and decontaminating the drum.

- Drainable chamber bottom, equipped with a holding tank of approx. 200 litre capacity with drainage pipe and DN 40 ball valve.

- DN 20 flange for drainage funnel valve.

- DN 40 flange for tank drainage valve.

- DN 25 flange for drum emptying.

- DN 25 flange for reserve use.

- DN 25 flange for drum filling.

- DN 15 flange for nitrogen flushing in the drum.

- Gas threaded sleeve ¾” for water/solvent inlet to chamber flushing gun.

- ATEX-certified cabin interior lighting lamp (zone 1)

A stainless steel trolley with drum handling roller conveyor is also supplied with the station.

CSV Containment provides tailor-made solutions for pharmaceutical and fine chemical sectors in terms of containment. For more info: containment@csv-ls.com