In the loading of pharmaceutical reactors, powder handling represents one of the most delicate stages of the production process.

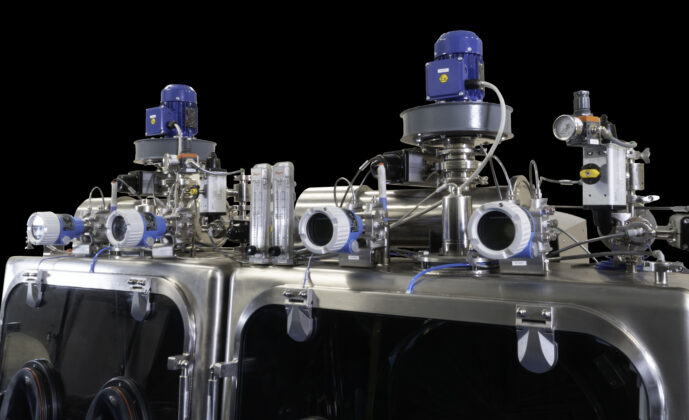

CSV Containment’s rigid isolators designed for pharmaceutical reactors are engineered to ensure that the loading operation takes place in maximum compliance with safety, cleanliness, and containment standards. They simultaneously protecting the operator, the product, and the working environment.

Made of stainless steel and designed according to GMP criteria, our glove boxes offer a level of containment that can reach up to OEB 5. Our rigid isolators ensuring an effective barrier against exposure to HPAPIs and against the risks of cross-contamination.

A Heart of Steel.

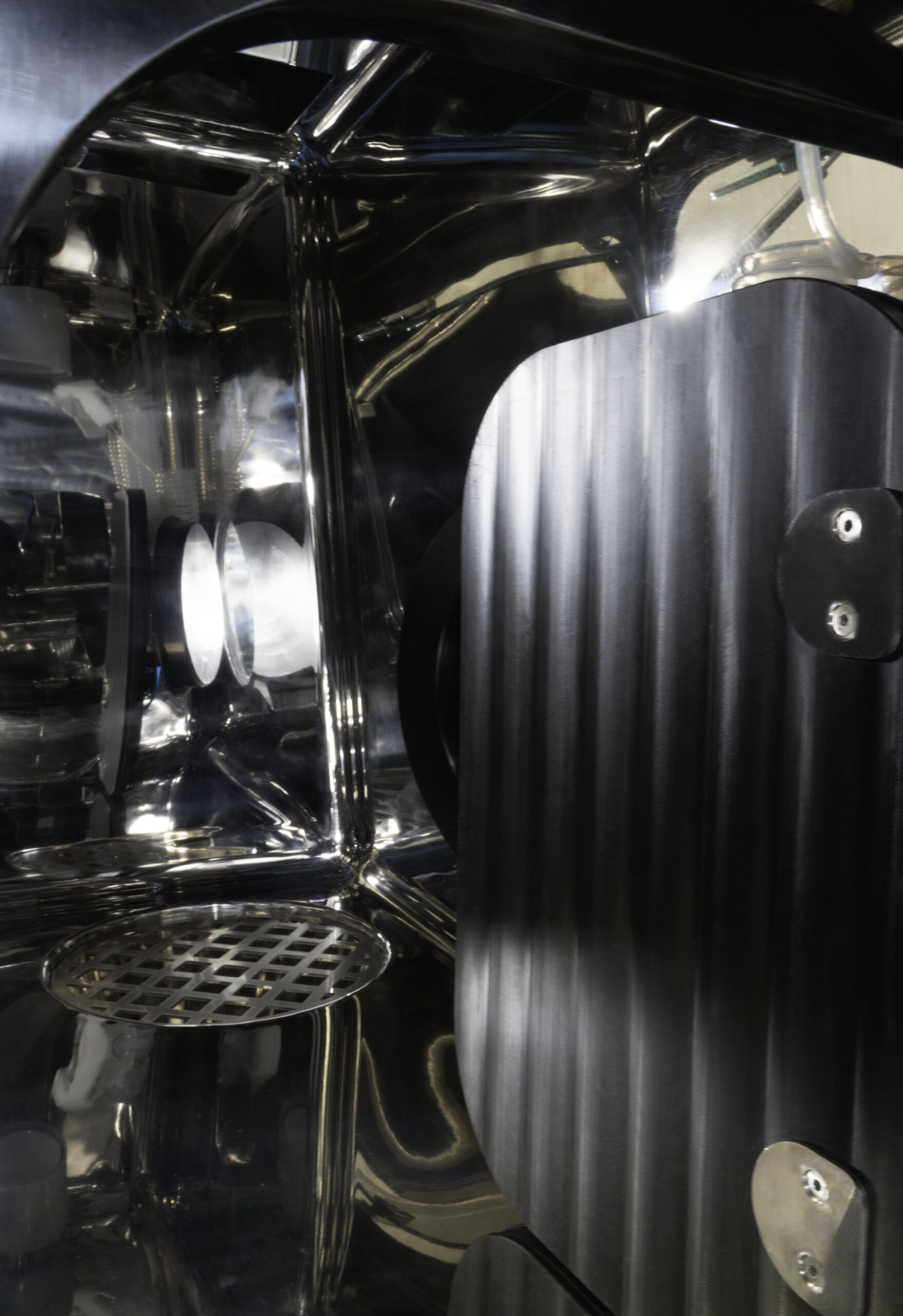

Inside the isolator, the material is loaded into the reactor in a closed and controlled manner. Indeed, the connection can be made using split valves or other contained transfer systems, depending on the product type, the process, and the various valve solutions available on the market.

The heart of the isolator is the rigid chamber under controlled negative pressure, ventilated through HEPA filters that maintain a safe and clean airflow. The ports, equipped with ergonomic gloves, allow the operator to perform the necessary maneuvers in complete safety, with full visibility and freedom of movement.

One Chamber or Two.

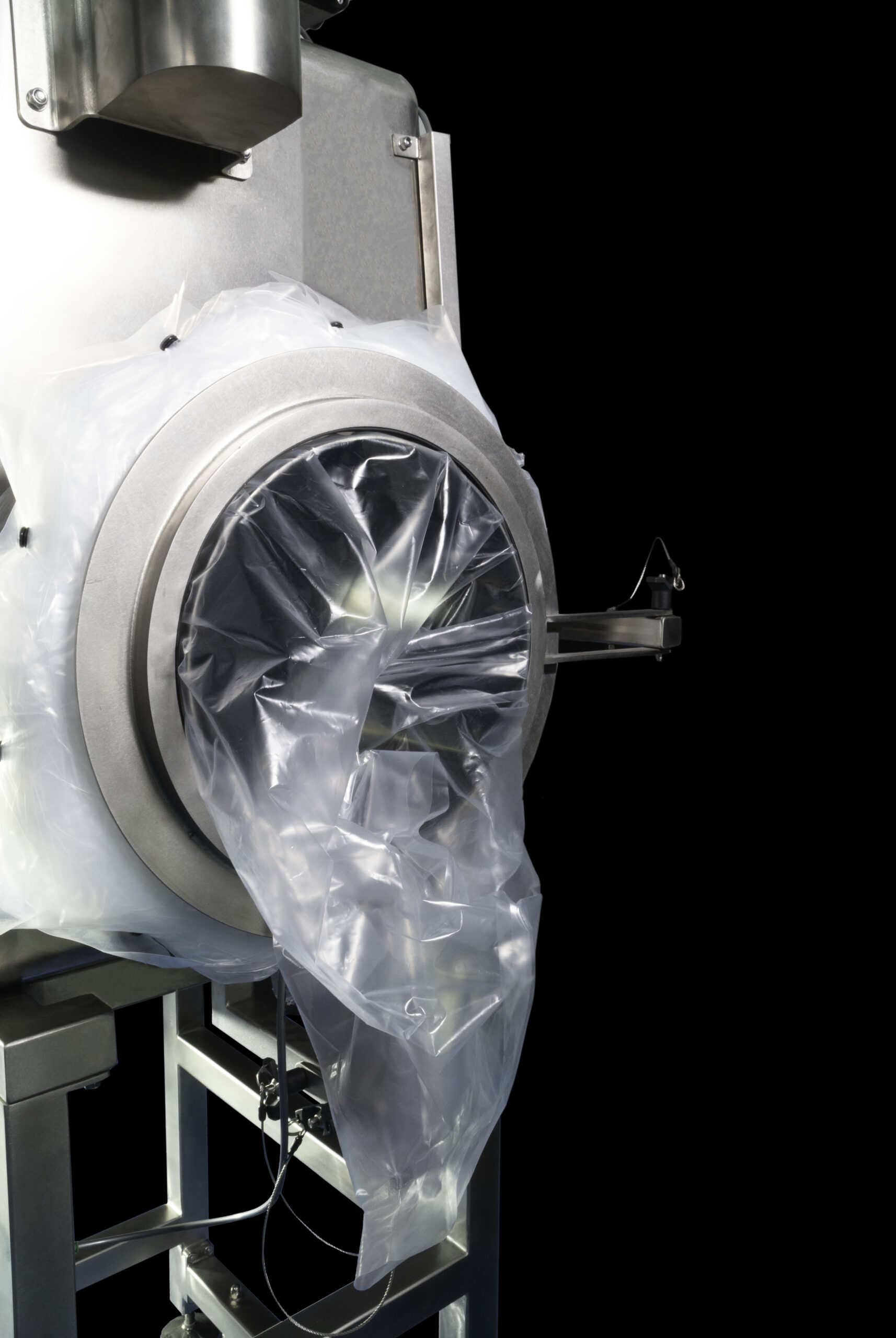

The addition of a pre-chamber ensures an extra margin of safety, as well as providing larger maneuvering spaces and the possibility of having additional bag-in and bag-out solutions. All internal doors, both between the chambers and towards the bag in/out routes, are also equipped with inflatable seals.

In addition to safety, great attention is dedicated to ease of cleaning. Smooth surfaces and the absence of stagnant areas allow for easy execution of CIP/WIP procedures, guaranteeing compliance with the highest standards of pharmaceutical quality.

Modular and Versatile.

Thanks to its modular structure and the high level of customization, reactor loading glove boxes can be designed and manufactured to perfectly adapt to every plant requirement. Another element of versatility is offered by the Drum Iris Technology system. The DIT® can transform the isolator’s drum loading point into a nearly universal access. This consolidated and patented solution made by CSV Containment allows for accommodating drums of different diameters. Various configuration options are available to make the system more complete (manual, automatic, with single or double iris).

In summary, our rigid isolators for reactor loading represent a complete and reliable solution for those who wish to combine maximum safety, operational efficiency, and regulatory compliance in the processes of pharmaceutical powder handling and transfer.

CSV Containment provides tailor-made solutions for pharmaceutical and fine chemical sectors in terms of containment. For more info: containment@csv-ls.com