When working with high-potency active pharmaceutical ingredients (HPAPIs), every move counts starting from powder loading.

Each step from powder loading to liquid transfer must be performed with precision and safety to protect both the product and the people handling it. CSV Life Science Group puts two of its top players on the field for this project: CSV Containment and Pharma Hub, representing containment technology and process plant expertise, respectively.

Pass of experience.

Pass of experience.

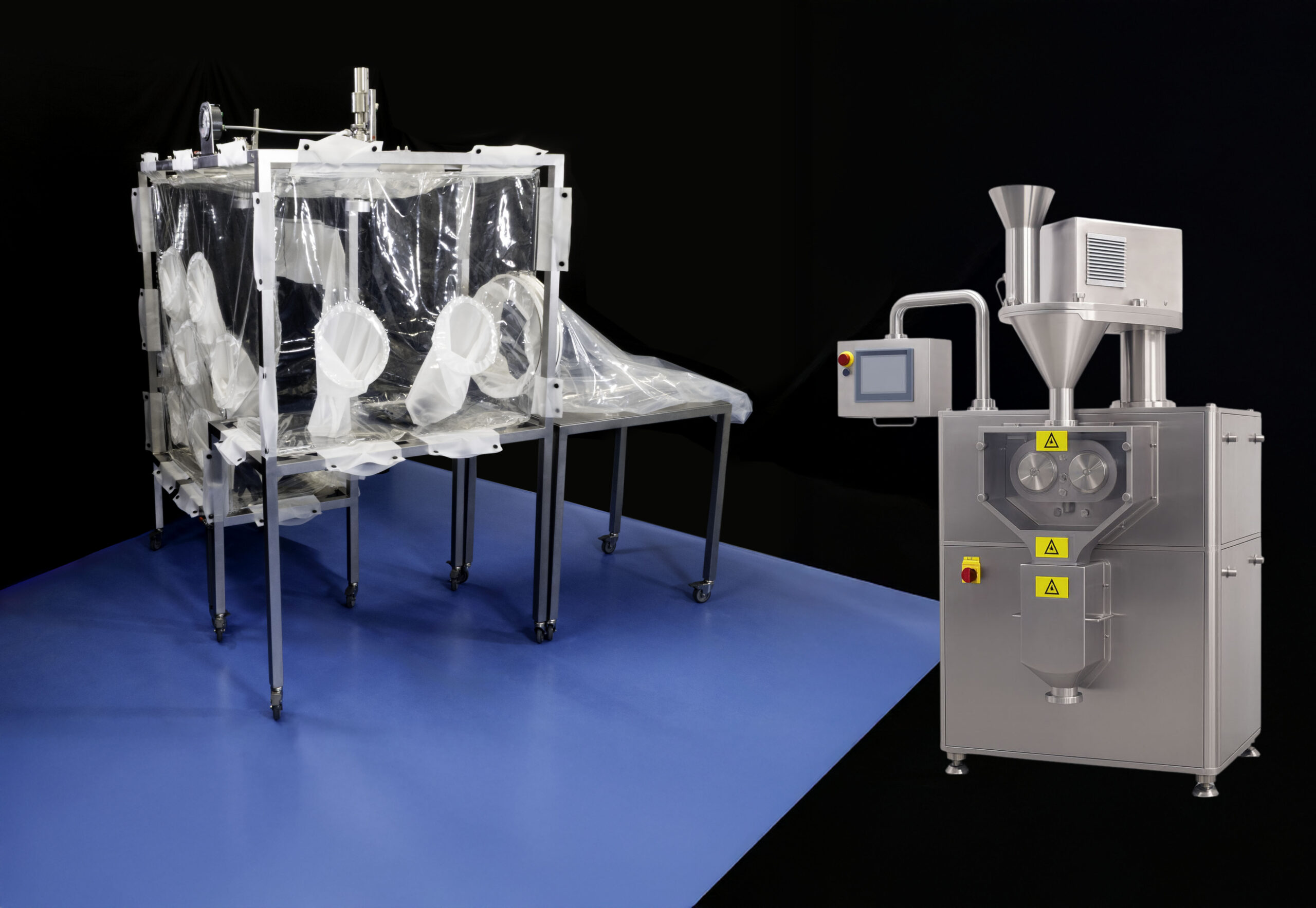

For this in-line loading station, CSV Containment developed a glove box where the product begins its journey through the DIT®. The manual double iris also available in a pneumatic version accommodates drums of various sizes. Once lifted by the drum lifter, they are safely opened inside the chamber. The dual iris system seals the drum securely, ensuring OEB5-level containment. At this point, the product is ready for transfer.

The Pass: Pharma Hub Takes Over.

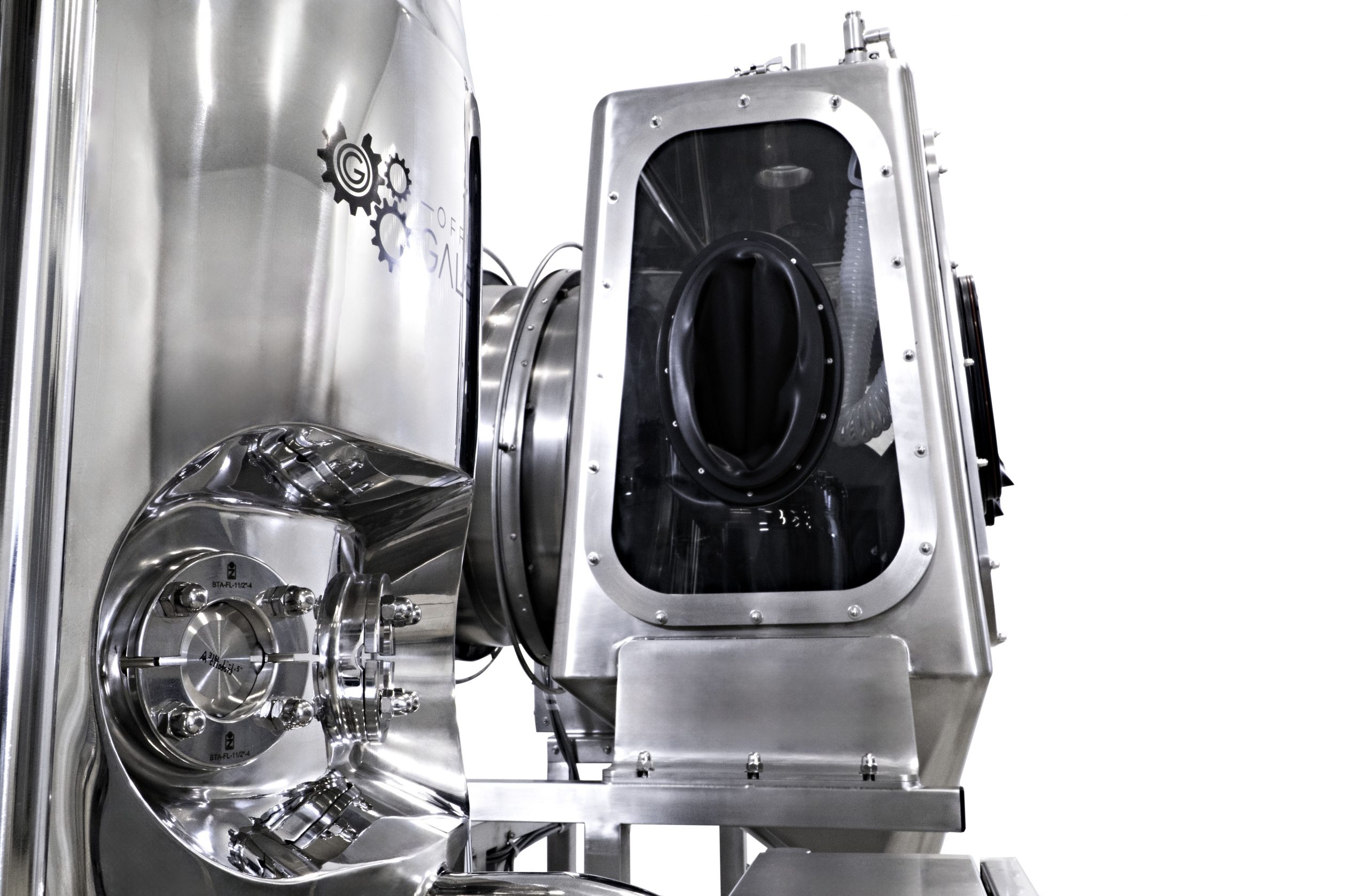

Here’s where Pharma Hub steps in. The product is transferred through a water stream that carries it into the tank, utilizing the Venturi effect the secret weapon of this integrated system. During this phase, mixing begins and continues inside a tank equipped with a magnetic agitator.

The mechanical construction is handled by Officine Galesso, Pharma Hub’s trusted partner for custom made equipment. The tank itself features a thermostatic jacket, insulation, and a mirror-polished finish. Inside, the active ingredient is blended with WFI (Water for Injection). These operations are fully automated, preset, and can be configured according to client specifications, including custom “recipes”.

Naturally, the entire system is CFR 21 Part 11 compliant, providing precise control and rapid access to electronic records, in line with FDA requirements.

A Closed System Open to Change.

In this setup, the active ingredient is recirculated within a fully closed system. However, the real strength of this system lies in its flexibility. The glove box can be repositioned farther from the tank if needed by simply adjusting the length of the connecting transfer line. But that’s not all: the glove box can also function as a completely standalone unit for other powder handling operations. This gives users the option to work with a fully integrated system or two independent units, depending on the specific process requirements.

CSV Containment provides tailor-made solutions for pharmaceutical and fine chemical sectors in terms of containment. For more info: containment@csv-ls.com