Is flexible high containment truly possible in terms of both material and operational versatility?

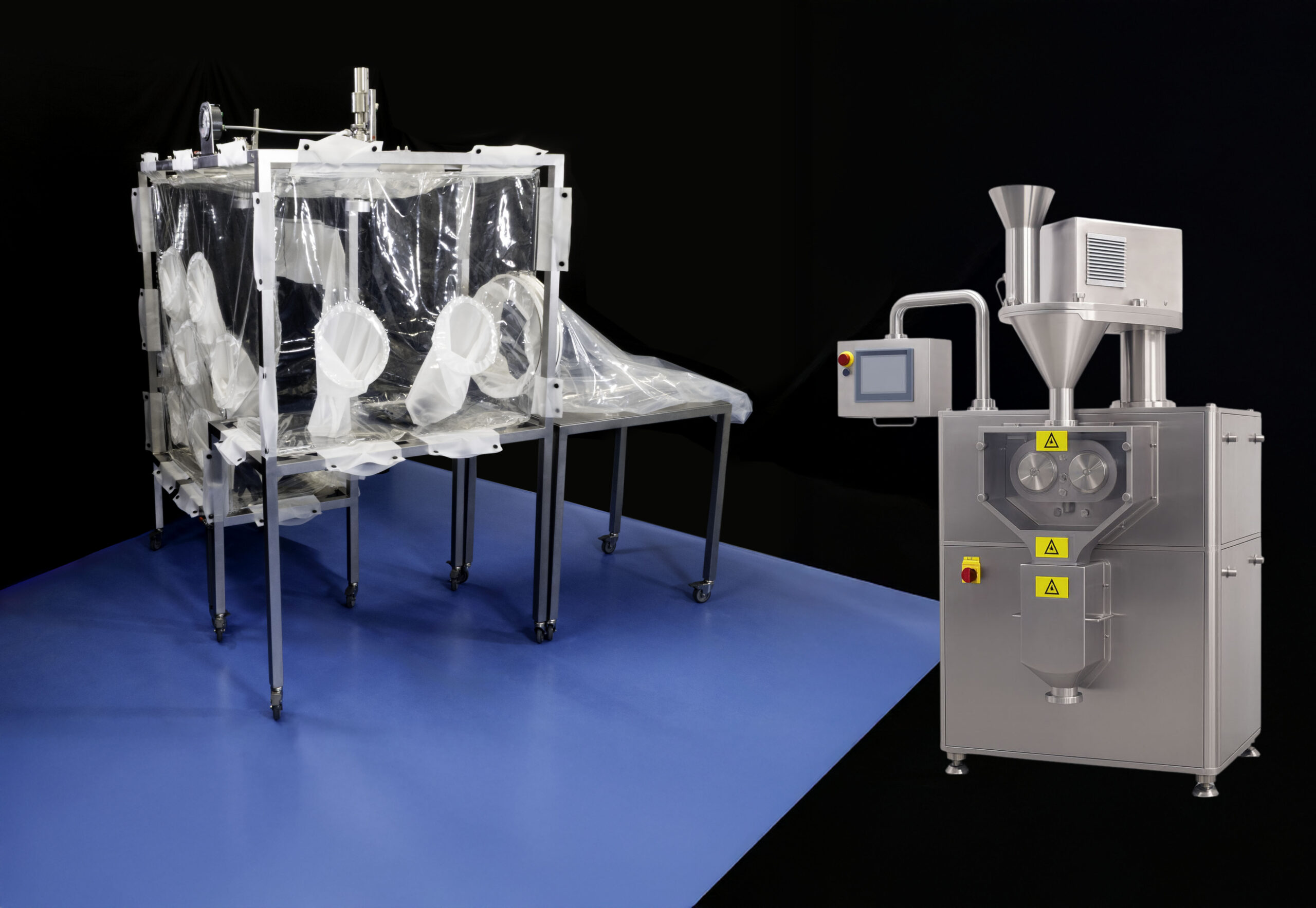

Far from being an oxymoron, flexible high containment is a tangible solution that enables increasingly stringent safety standards in pharmaceutical manufacturing. The world of glove bags makes it possible to reduce both time and cost, offering the agility needed to stay ahead of the market or rapidly respond to evolving regulatory demands. CSV Containment’s glove bags are designed to reach OEB4 containment levels, with configurations available for OEB5 through integrated pressure control systems. But high containment is not limited to isolators alone — it extends to the entire process chain, including containment-grade valves for material discharge. In this space, the market offers highly advanced and very interesting solutions.

Disposable Components Always Available.

Single-use isolators and valves offer significant advantages over rigid systems. Their primary strength lies in configurability: should adjustments be needed for ergonomics, workflow, or spatial requirements, modifications can be made quickly and affordably before the next production cycle.

Single-use isolators and valves offer significant advantages over rigid systems. Their primary strength lies in configurability: should adjustments be needed for ergonomics, workflow, or spatial requirements, modifications can be made quickly and affordably before the next production cycle.

CSV Containment’s glove bags are mounted on custom-built support frames, which can include telescopic legs to align the flexible isolator with reactors more comfortably. Each structure is also equipped with an interface for market standard high-containment valves, compatible via clamp connections. In other cases, thermosealed sleeves on the isolator allow direct connections, offering even greater design freedom.

Maximum Flexibility in All Directions.

The true flexibility of glove bag systems also lies in their mode of use. Depending on the type of valve or device to interface with, it’s possible to move freely across different configurations.

For example, when discharging into a reactor, an active ChargePoint valve is ideal: thanks to its robustness and reliability, it can be permanently installed at the port and then accessed by a passive unit for safe material transfer. For this same application, using a lightweight disposable active valve in combination with a flexible isolator offers both efficiency and safety. Once again, telescopic isolator structures enable precise positioning and easy access.

When the setup is reversed — for instance, when discharging from a glove bag into bottles or bags — 2-inch or 4-inch active valves offer practical and safe solutions. A 2-inch stainless steel valve provides a good balance between weight and durability, making it ideal for agile handling in small-scale operations.

A Complete Single-Use Ecosystem.

Glove bags integrate seamlessly with disposable valves and bags of all sizes, supporting a fully single-use supply chain. A standout example of versatility is the Andocksysteme solution, which uses a double disposable passive system to couple Avax valves with A-Cube bags or other devices, ensuring secure and compliant loading and unloading operations.

Further expanding the range of disposable solutions are cassette-type disposable valves, with compatible accessories and bags available in various configurations. Thanks to its deep expertise and strong collaboration with industry partners, CSV Containment offers a wide array of flexible solutions tailored to every requirement — ensuring reliable performance throughout the entire containment lifecycle.

Tailor-Made Containment, Built Together.

Whatever your needs or preferences for a specific system, we are ready to work with you to co-develop the best containment solution for your process.

CSV Containment provides tailor-made solutions for pharmaceutical and fine chemical sectors in terms of containment. For more info: containment@csv-ls.com