The past 12 months have seen the industry experience an ever-growing demand for high potency active pharmaceutical ingredient (HPAPI) and drug manufacturing. This increasing need has been fortified by the biotech boom that has been gaining momentum in recent years. This demand has come with its challenges and created a need for more advanced containment strategies across the development and manufacturing of potent ingredients and products. Here we explore what is currently being done to address containment challenges.

1. New technology and facilities

There have been many technological advancements in containment strategies and high potency facility management. Some of the more common solutions include the creation of rigid and flexible barrier isolators, which offer a new level of containment security, and extracted booths, which give a secondary level of protection when dealing with high potency ingredients.

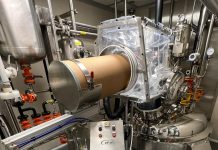

Another advancing technology is that of split butterfly valves (SBV). This unique technology is versatile and can be used alone or integrated into other containment solutions. They enable the safe transfer of potent compounds into bags and containers, which are then transferred to downstream processes.

SBVs have evolved over the last 25 years alongside increasing demands in containment performance. Innovative design has removed the risk of airborne exposures which is integral to achieving high containment. The reliability and growing awareness across the industry has supported the wide-use of SBVs.

2. Safety and efficiency

Eliminating the risks posed by handling such high potency ingredients will always be a top priority for the containment sector. Risks during materials transfer range from cross contamination to dangerous health issues posed if operators and/or their environments come into direct contact with such aggressive materials and compounds. Therefore, it is not surprising that advancements in technology, like SBVs, have been focused on protection and safeguarding. The increasing use of SBVs has meant there is now less dependence on using personal protective equipment (PPE) and respirators, as manufacturers can now contain and control the area surrounding the potent compound and therefore shield the working environment for the operator.

When new technologies are employed, the correct operation of the installed containment equipment is fundamental. Ensuring that appropriate training is conducted amongst employees and that these operations are monitored is also vital. Training and monitoring should remain consistent and be ongoing at all times during the system’s use, and not just during its implementation. This will help to not only secure operator safety and ensure high containment performance, but also increase efficiency. For example, regular monitoring creates the ability to identify potential issues before they arise.

3. The outsourcing sector

More frequently, manufacturers have found themselves in a situation whereby either their facilities have not met the requirements of handling HPAPIs or they have not had the capacity to deal with the influx of demand. Paired with the pressures of technological advancements, many manufacturers have found themselves unable to accommodate or afford facility upgrades. As the industry diversifies, bespoke equipment has also become another difficulty for smaller manufacturers who have struggled to meet niche demands. These trends, combined, have led to increasing needs to outsource to specialist CMOs within the sector, to ensure that the balance between health and safety is paired with productivity and output.

4. The future

If we try to predict the future in containment, the possibilities seem endless. From technological advancements in wireless technology that could lead to completely eliminating operators out of the containment equation, to the increased use of disposable technology, the future looks innovative. The most likely progression in the near future will be in the direction of fully closed systems and totally contained operations which have mainly been introduced thanks to an increase in highly potent biotechnological developments.